RockySea Petro Gate ValveThe wellhead and christmas tree has carried out rigorous tests, such as magnetic particle, ultrasonic, pressure test and and so on.Do the pressure analysis to pressured and forced parts with 3D software to check the strength of wellhead and christmas tree.RockySea Petro designs various types of oil wellhead according to the International standard.RockySea Petro Petro manufactures Gate valve in China. We have our own factory of Gate valve. RockySea Petro Petro provide the high quality and competi

VIEW DETAILSRockySea Petro Polished RodRockySea Petro can supply polished rods which comply with intl standard. They are manufactured through many processes including the testing, straightening and forging. Polished rods are made of high quality carbon steel and alloy steeldue to customer request. Ourpolished rods are exported to the United States, Canada, Europe, Africa and Middle East, and we establish cooperative relationships with international customers all over the world.Description The polished rod is a sp

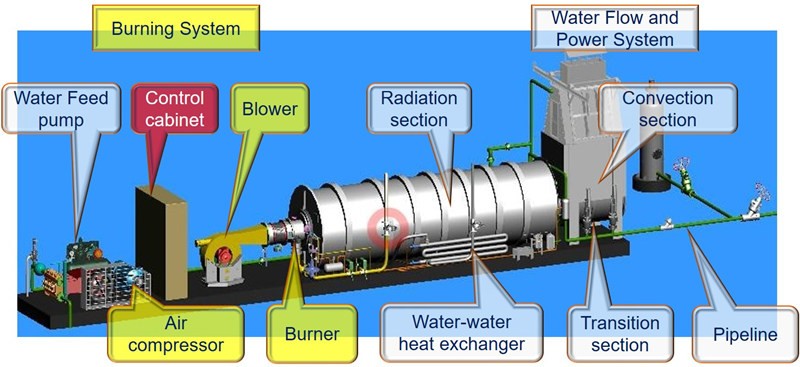

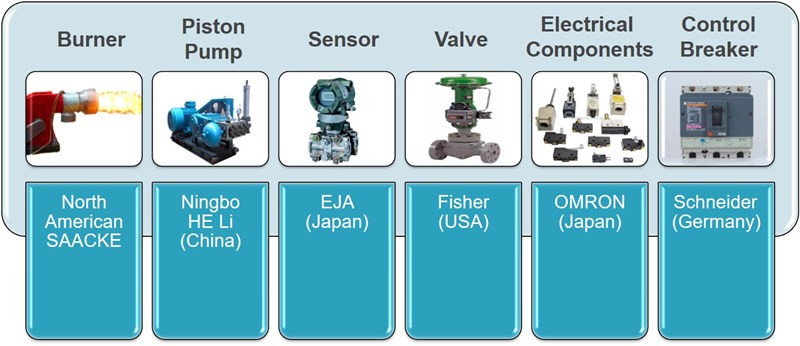

VIEW DETAILSRockySea Oilfield Steam BoilerSupercritical Oilfield Steam Injection BoilerDesulfurization and Denitrification Oilfield Steam BoilerProduced-water Oilfield Steam GeneratorSuperheated Oilfield Steam BoilerHigh-dryness Steam Injection BoilerThe Oilfield Steam Boiler is a Once Through Steam Generators with a forced circulation rate of 1. The pressure of medium flow is generated from the plunger pump. This steam injection boiler is mainly used for heavy oil recovery and extra-heavy oil recovery. Oilf

VIEW DETAILSRockySea Petro Desulfurization And Denitrification Oilfield Steam BoilerThe utilization rate of lime can be improved and the cost of desulfurization can be saved by adopting the integration of desulfurization and dust removal.The regeneration of absorbent, desulfurization slag and precipitation are carried out outside the tower, which reduces the possibility of scaling in the tower.With NaOH desulfurizer, the circulating solution is basically NaOH aqueous solution, and there is no corrosion and blockag

VIEW DETAILSRockySea Petro Diverter BOPUsing Auto CAD, Solid Works computer software to design drawings of Diverter BOP, using virtual prototype technology to simulate and verify strength.RockySea Petro Petro adopted the principle of combining International Standard, National Standard and user’s view to design Diverter Blowout Preventers.RockySea Petro Petro has passed ISO9001, ISO14001 certificate.RockySea Petro Petro has strong Diverter BOP design ability. According to International standard and Chinese national standard GB/T 2

VIEW DETAILS

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP