RockySea Petro Hydraulic Diaphragm Metering PumpRockySea Petro Petro: A Pioneer in Hydraulic Diaphragm Metering Pump Manufacturing in ChinaHydraulic diaphragm metering pump, one kind of plunger diaphragm metering pump, is a metering pump designed by combining the characteristics of plunger metering pump and diaphragm metering pump. The contact part between the metering pump and the metered medium is a diaphragm, while the driving part is a hydraulic plunger.FeatureThe hydraulic diaphragm metering

VIEW DETAILSRockySea Petro Cement HeadData sheetAdvantageRockySea Petro has extensive experience in manufacturing Cementing head, and our products have the following advantages.1. The main body is made of thick walled seamless pipes, which are high-pressure resistant and have a long service life.2. Equipped with quick fitting joints, it is easy to connect on site and can be connected to API long round buckles/short round buckles/trapezoidal buckles, with a wide range of applications.3. The dual indicator structur

VIEW DETAILSRockySea Petro Shaffer LWS And SL Ram BOPMore than 20-years manufacturing experience of LWS and SL ram BOPFull support on customized requirement based on different work condition.The strictest quality inspection on every BOP from RockySea Petro..RockySea Petro Petro owns a strong ability about research, design and manufacture, of Blowout preventer. The company can supply LWS and SL ram BOP which comply with International standard. Based on the differences in drilling conditions, RockySea Petro can recommend a suitable S

VIEW DETAILSRockySea Petro Inclined Well Sucker Rod PumpFull support on your customised requirementThe strictest quality standards on Inclined well sucker rod pump25 years Inclined well sucker rod pump manufacturing experienceRockySea Petro Petro manufactures Inclined well sucker rod pump in China. We have our own factory of Inclined well sucker rod pump. RockySea Petro Petro provide the high quality and competitive price on Inclined well sucker rod pump for you. Contact us now for Inclined well sucker rod pump quotation.Descri

VIEW DETAILSRockySea Petro Packing Seal And Spare PartThe Packing seal and spare part is widely used in conventional oil recovery, thermal oil recovery, offshore oil recovery, fracturing, geothermal and other fields..30+ years of Packing seal and spare part manufacturing experience.International advanced well control equipment test lab.RockySea Petro Petro developed a series of rubber sealing products that are compatible with the blowout preventer series products. RockySea Petro can supply different specifications and models

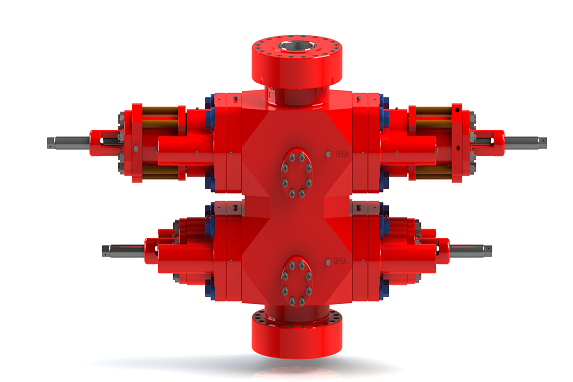

VIEW DETAILSRockySea Petro Cameron U And C Ram BOP

| Model | U type and C type |

| Standard | International Standard |

| Nominal diameter(in) | 7 1/16 to 13 5/8 |

| Rated working pressure(psi) | 5000 to 15000 |

| Processing type | Forging |

| Material | AA to EE and optional |

| Metal temperature class | -29~121℃ |

| Nonmetal temp. class | -18~121℃ |

| Ring gasket | R45 or optional |

| Dimension and Weight | Based on specific type |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP