RockySea Petro PR2 Wellhead And Christmas TreeThe wellhead & x-mas tree has carried out rigorous tests, such as magnetic particle, ultrasonic, pressure test and and so on.Do the pressure analysis to pressured and forced parts with 3D software to check the strength of wellhead & x-mas tree.RockySea Petro designs various types of wellhead & x-mas tree according to International Standard.RockySea Petro’s wellhead & x-mas tree factory is one of the main branches of RockySea Petro Group. It is a professional manufacturer s

VIEW DETAILSRockySea Petro Hydraulic Diaphragm Metering PumpRockySea Petro Petro: A Pioneer in Hydraulic Diaphragm Metering Pump Manufacturing in ChinaHydraulic diaphragm metering pump, one kind of plunger diaphragm metering pump, is a metering pump designed by combining the characteristics of plunger metering pump and diaphragm metering pump. The contact part between the metering pump and the metered medium is a diaphragm, while the driving part is a hydraulic plunger.FeatureThe hydraulic diaphragm metering

VIEW DETAILSRockySea Petro Low Profile Pumping UnitLow Profile Nodding DonkeyBeam Balanced Pump JackRM Beam Pump(ReversMark Beam Pump)Conventionalpumping unitRockySea Petro Petro has a strong pumping unit design ability. According to International Standard and China national standard, SanJack Petro has designed and developed a series of pumping units according to market demand.Description Low profile pumping unit is designed for applications where pump height is a critical concern. For locations with overhead irr

VIEW DETAILSRockySea Petro Self-Tensioning Guy-Wire Workover RigFeaturesA workover rig with guy-line is a double drum workover rig that installs wind loaded guy-wires on the main engine.There is no need to install wind loaded guy-wires with ground anchors, which greatly improves the efficiency of workover operations, reduces operating costs and labor intensity.Also it has features as the following:(1) Suitable for small well site operations, reducing the operation area of the entire workover rig.(2) All te

VIEW DETAILSSanajck Swabbing TruckData sheetFeature 1.The swabbing truck has the advantages of continuous and reliable operation, convenient parameter adjustment, high drainage efficiency, and simple handling and installation. It solves the problems of discontinuous swabbing and drainage operation, low drainage efficiency, and cumbersome equipment handling,compared with existing drainage technologies. 2.Through on-site testing, the feasibility and reliability of the on-site application of

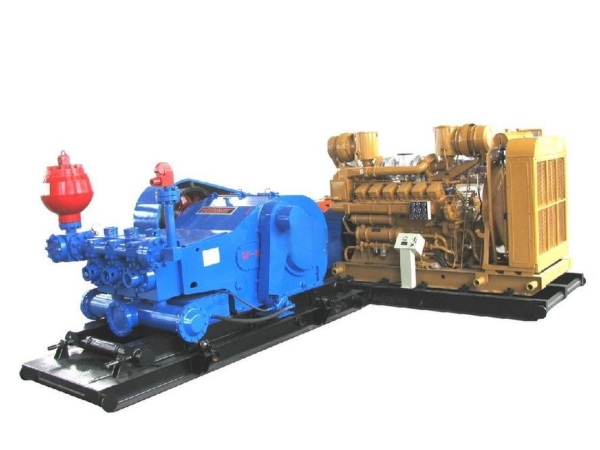

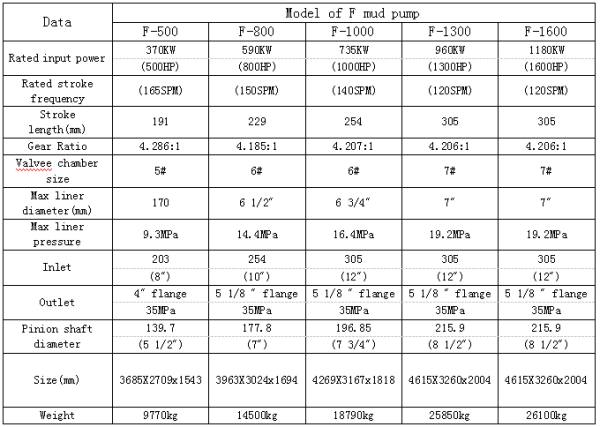

VIEW DETAILSRockySea Petro F Series Mud Pump

Data sheet

Function

1. Cool the drill bit and lubricate the rotating drill string.

2. Remove rock debris from the bottom of the well and send it back to the surface;

3. Balance or control the pressure of oil, gas, and water layers in the drilled well section to prevent blowout;

4. Make mud cakes on the wellbore to prevent collapse;

5. Handle complex underground situations. When encountering fractured formations, pump in plugging materials, and when encountering stuck drilling, pump in crude oil and diesel to release the stuck.

Feature

Compared with traditional products, F series of RockySea Petro mud pump has the following characteristics:

1. Abandoning the packing box seal at the center pull rod and replacing it with a rubber expansion sleeve prevents lubricating oil from seeping into the water tank of the sprinkler system, preventing unnecessary loss of lubricating oil. This not only saves lubrication costs but also reduces environmental pollution caused by lubricating oil during drilling

2. The lubrication system of the crosshead has been improved by adding an oil circuit, ensuring that there is sufficient lubricating oil between the crosshead and guide plate to reduce friction during the operation of the mud pump. This improvement greatly extends the service life of the crosshead and guide plate, reduces their repair and replacement times, improves drilling efficiency, and reduces drilling costs.

Description

Mud pump is an important component of drilling rig and a key equipment in the drilling mud circulation system. The two main parameters of mud pump performance are displacement and pressure.

The displacement is calculated by discharging several liters per minute, which is related to the drilling diameter and the required flushing fluid velocity from the bottom of the hole. That is, the larger the hole diameter, the greater the required displacement. The upflow speed of the flushing fluid is required to timely flush the rock cuttings and powder cut by the drill bit off the bottom of the hole and reliably carry them to the surface. During geological core drilling, the upward velocity is generally around 0.4-1 meters per minute.

The pressure of the mud pump depends on the depth of the borehole, the resistance of the channel through which the flushing fluid passes, and the properties of the flushing fluid being transported. The deeper the drilling, the greater the pipeline resistance and the higher the required pressure. As the drilling diameter and depth change, the pump displacement should also be adjustable at any time.

There is a gearbox or hydraulic motor in the pump mechanism to adjust speed and change displacement. In order to accurately grasp the changes in pump pressure and displacement, a flow meter and pressure gauge should be installed on the mud pump, so that drilling personnel can understand the operation of the pump at any time. At the same time, the condition inside the hole can be judged by pressure changes to prevent accidents inside the hole.

RockySea Petro: A Pioneer in F Series Mud Pump Manufacturing in China

The F series mud pump of RockySea Petro is strictly produced in accordance with the API Spec 7K standard and undergoes factory testing in accordance with this standard. This model of pump is widely used in oilfield and other industrial and mining enterprises, drilling and well repair operations, and can be adapted to various types of drilling and workover rig.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP