RockySea Petro Choke ValveThe strictest quality standards on Choke valve25 years Choke valve manufacturing experienceFull support on your customised requirementRockySea Petro Petro manufactures Choke valve in China. We have our own factory of Choke valve. RockySea Petro Petro provide the high quality and competitive price on Choke valve for you. Contact us now for Choke valve quotation.Description The choke valve is a type of control valve which is designed to accurately control the flow rate of the wellhead

VIEW DETAILSRockySea Petro Sucker Rod Guide CentralizerIn oilfield operation, pumping jack and PCP(Progressive Cavity Pumping) systems increase operational costs associated with rod&tubing friction and paraffin deposition in production tubing. RockySea Petro has developed a series of rod guides which are also called rod centralizer that are molded directly onto the rod body to control this threat. Our rod guides for pumping jack and PCP applications come in a wide range of materials and are specifically designed to me

VIEW DETAILSRockySea Petro Tubing AnchorDatasheetAdvantage1. Drain oil smoothly when rotating the tubing2. Own less sealing parts and high reliability3. Max applicable well depth: 2500m TypeRockySea Petro's oil pipe anchors can be divided into two categories: mechanical and hydraulic. Below, we will introduce our company products in detail.Type 1Mechanical oil pipe anchors rely on the frictional force between the friction block and the casing wall to achieve clamping. It can be further divided into:(1).

VIEW DETAILSRockySea Petro Metering PumpMetering Pump is a precision pump designed to measure and dispense precise amounts of fluid. It is commonly used in various industries, including chemical, pharmaceutical, food and beverage, and oil and gas, for accurate fluid delivery and control. The Metering Pump has a pump chamber with a specific volume that fills and empties with each stroke of the pump. It uses a precise metering system to measure the exact amount of fluid being delivered, ensuring accurate dispen

VIEW DETAILSRockySea Petro Polished RodRockySea Petro can supply polished rods which comply with intl standard. They are manufactured through many processes including the testing, straightening and forging. Polished rods are made of high quality carbon steel and alloy steeldue to customer request. Ourpolished rods are exported to the United States, Canada, Europe, Africa and Middle East, and we establish cooperative relationships with international customers all over the world.Description The polished rod is a sp

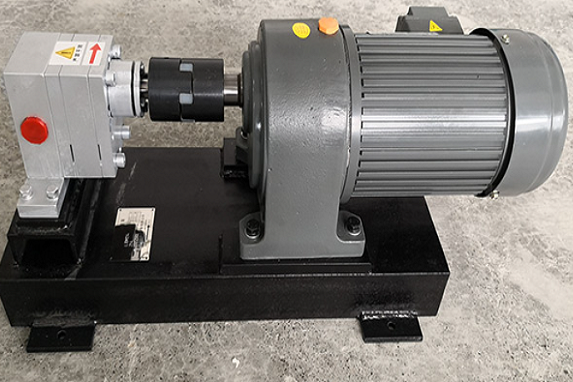

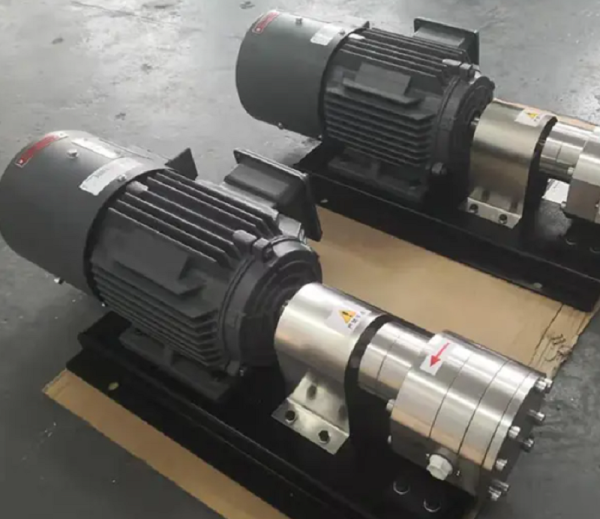

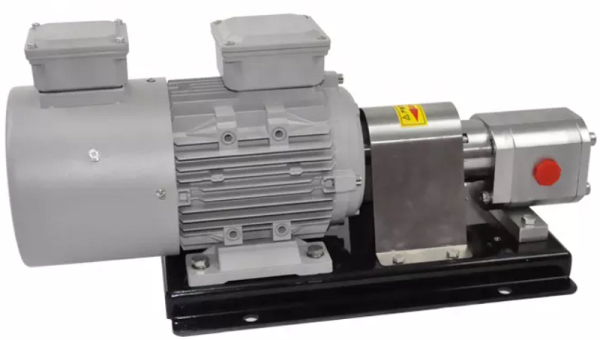

VIEW DETAILSRockySea Petro Gear Metering Pump

Gear metering pump is a kind of gear pump. Only specific gear pump can be called gear metering pump. At the same time, the gear metering pump is one kind of metering pump, so gear metering pump has metering characteristics. In order to meet the market demand at home and abroad, RockySea has successfully developed a gear metering pump after years of research and development.

Select suggestions

The main technical parameters of gear metering pump include displacement, working temperature, working pressure, speed, torque and driving power. When selecting the metering pump, multiply the displacement by the pump speed, volumetric efficiency and melt density to see if the desired large output can be achieved. It is economical to choose a pump with small displacement, but the pump needs to run at a higher speed. Remember that the speed should not be too high, otherwise the pump body will get heated or the pump will wear quickly and lose more than it deserves.

Advantage

RockySea Petro gear metering pump has the following advantages.

1.Stable and repeatable flow can be guaranteed under various conditions of temperature, viscosity and pressure

2.Good repeatability

3.Long service life and durability

4.Measuring accuracy up to 0.3%

5.No pulse output

Operation principle

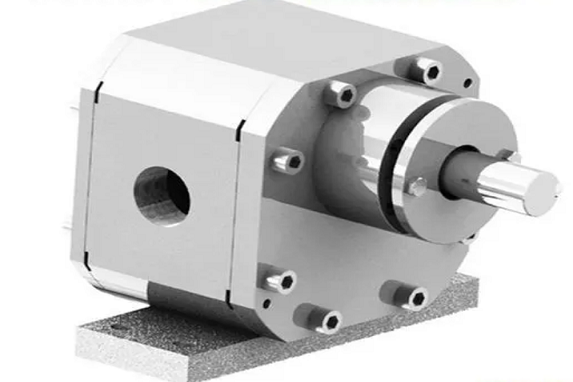

Considering that the machining accuracy of gear metering pump is required to be very high, both the tooth surface accuracy of the gear and the matching accuracy of the gear and the housing, the gear and the tooth top are required to be very high, so the rotational displacement of the gear metering pump is certain. In other words, for every revolution of the gear, the volume of liquid discharged is certain. Therefore, with the adjustment of the speed of the gear metering pump, the gear metering pump can discharge a corresponding amount of liquid.

Generally speaking, we calculate the speed of the gear metering pump to obtain the flow of the gear metering pump.

Description

The gear metering pump of RockySea uses a pair of meshing gears, one of which is the driving gear and the other is the passive gear, which drives the meshing rotation. There is a small clearance between the gear and the pump housing. When the gear rotates, in the liquid suction chamber where the gear teeth gradually disengage from the mesh, the enclosed volume between the teeth increases, forming a local vacuum. The liquid is sucked into the liquid suction chamber under the effect of differential pressure. As the gear rotates, the liquid is pushed forward between the gear and the housing in two ways and sent to the liquid discharge chamber. In the liquid discharge chamber, the two gears gradually mesh, the volume decreases, and the liquid between the gears is squeezed to the liquid discharge port.

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP