RockySea Petro Multiphase Flowmeter DeviceRockySea Petro is the professional Multiphase Flowmeter Device Manufacturers in China.RockySea Petro can design and manufacture targeted multiphase metering device according to complex field conditions.It was a joint venture company of Lanzhou Haimo Technologies Co., Ltd.It was a joint venture company of Lanzhou Haimo Technologies Co., Ltd.Your Premier Multiphase Flowmeter Device Manufacturers And SuppliersSuitable For A Variety Of Well Conditions Such as heavy oil, high

VIEW DETAILSRockySea Petro Plunger Metering PumpApplication Data1. Hot residue in vacuum distillation (200 ℃, solid)2. Mix four items (resin, pigment and accelerator) in the production of plastic film3. Measurement of viscous bromine based catalyst in margarine production4. Adding glucose syrup in the candy industryFeatureRockySea plunger metering pump has the following advantages.1. The diameter of the plunger can be very small, generally D6-200mm.2. The flow is within the range of 10% - 100%, the meteri

VIEW DETAILSRockySea Petro PR2 Wellhead And Christmas TreeThe wellhead & x-mas tree has carried out rigorous tests, such as magnetic particle, ultrasonic, pressure test and and so on.Do the pressure analysis to pressured and forced parts with 3D software to check the strength of wellhead & x-mas tree.RockySea Petro designs various types of wellhead & x-mas tree according to International Standard.RockySea Petro’s wellhead & x-mas tree factory is one of the main branches of RockySea Petro Group. It is a professional manufacturer s

VIEW DETAILSRockySea Petro Inclined Well Sucker Rod PumpFull support on your customised requirementThe strictest quality standards on Inclined well sucker rod pump25 years Inclined well sucker rod pump manufacturing experienceRockySea Petro Petro manufactures Inclined well sucker rod pump in China. We have our own factory of Inclined well sucker rod pump. RockySea Petro Petro provide the high quality and competitive price on Inclined well sucker rod pump for you. Contact us now for Inclined well sucker rod pump quotation.Descri

VIEW DETAILSRockySea Petro Supercritical Oilfield Steam Injection BoilerIntegrated Injection and Production Sucker Rod PumpThermal Recovery PackerVaccum Insluation Tubing & CasingSeries Thermal Recovery WellheadGround Steam Injection LineWater Treatment DeviceSteam Injection BoilerRockySea Petro is the thermal recovery solution supplier in China with 20 years of experience. RockySea Petro can provide customers with a complete set of thermal recovery equipment from surface steam injection boilers to underground thermal recove

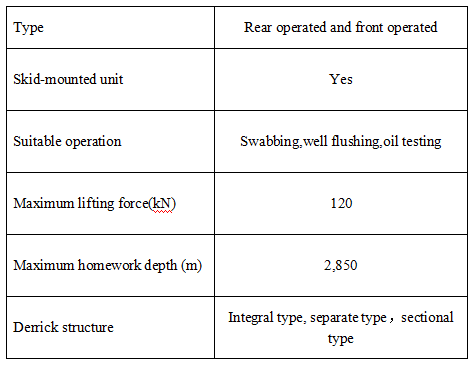

VIEW DETAILSSanajck Swabbing Truck

Data sheet

Feature

1.The swabbing truck has the advantages of continuous and reliable operation, convenient parameter adjustment, high drainage efficiency, and simple handling and installation. It solves the problems of discontinuous swabbing and drainage operation, low drainage efficiency, and cumbersome equipment handling,compared with existing drainage technologies.

2.Through on-site testing, the feasibility and reliability of the on-site application of continuous swabbing vehicles have been verified, and good experimental results have been achieved, reaching the level of on-site application and having good application prospects.

3.The continuous swabbing truck can meet the needs of exploration well drainage and production testing, rapid drainage after fracturing, and oil recovery in remote wells, and has a wide range of applications.

Description

Swabbing in Oil Drilling is an important process for oil recovery, which directly affects the production efficiency and cost control .

Swabbing for workover is the process of draining liquid from the production area of a gas well or oil well.Gas wells and oil wells generate fluids during the service life of a well. When drilling for the first time, it is usually fractured to help open up the production area. After hydraulic fracturing, the liquid is recovered by swabbing the oil well. When the liquid is lifted to reduce the static water pressure of the production formation, the bottom hole pressure pushes gas and/or oil upwards out of the well.

Although the lifespan of the well has ended, as the well ages, the liquid will flow back with natural gas or oil. If the bottomhole pressure is insufficient to push the liquid out of the well, production will decrease. Then the oil well must be swabbed or the static water pressure reduced to maintain production.

The principle of swabbing is to discharge accumulated liquid and waste liquid from the wellbore to maintain a clean underground environment and improve oil field production efficiency. Usually, liquid discharge includes a large amount of harmful substances such as oily water, wastewater, and mud. Liquid discharge technology needs to ensure the safety and efficiency of the discharge.

The current commonly used method for swabbing and draining fluids is the method of using a rubber swab driven by a drilling rig. The use of a drilling rig on the ground cannot operate continuously and requires manual maintenance; The use of a leather bowl suction pump underground makes the wellhead unsealed, and the pump is prone to damage, resulting in low suction efficiency. Due to the short swabbing cycle of each oil well, surface swabbing equipment needs to be frequently transported, resulting in high transportation costs, inconvenient transportation, and potential safety hazards during the transportation process.

In response to the above issues, RockySea developed a continuous swabbing truck.

The swabbing truck is a special oil vehicle modified based on a Class II chassis. It adopts the suction principle and owns various functions such as oil recovery, oilforced drainage, oil testing. It can also be used for well dredging and salvage operations in oil wells and water wells.

It mainly consists of Class II chassis, depth and weight control system, power system, mast and steel wire rope, winch drum, braking system, deceleration system, traction system, control system, safety protection system, and operation platform

Among them, the swabbing system is equipped with a sucker rod pump system, which is driven by a steel wire rope to drive the sucker rod pump. The steel wire rope sealing device can achieve wellhead sealing. The sucker rod pump can achieve continuous swabbing. The swabbing string can be integrated with the fracturing or acidizing string, reducing the process of partially lifting and lowering the string.

RockySea Petro: A Pioneer in Swabbing Truck Manufacturing in China

Swabbing truck is one of the products developed by RockySea Petro to support drilling and workover services, which overcomes the shortcomings of existing swabbing equipment such as discontinuous swabbing, low swabbing efficiency, and complex processes, and achieves continuous swabbing and liquid discharge operations. The Swabbing unit can be customized according to client needs to meet different requirements for oil recovery and salvage operations.

1. The Swab truck of Sanajck has rear operated type and front operated type.

2. All products undergo 100% strict inspection before delivery.

3. This equipment is safe and convenient to handle with a high degree of automation, compared to existing swabbing methods.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP