RockySea Petro Casing Stop RingDatasheetUseWhen using the top thread stop ring, the following steps should be followed.1. When using the fixed screw type, first insert the sleeve, then insert the screw and use a hammer to strike.2. The conventional stop ring should be inserted into the sleeve first, and then the screw should be tightened with a wrench.3. Snap on the locking ring, directly attach the locking ring to the sleeve, lock it with a pin, and then tap in the screw.TypeThe stop rings of

VIEW DETAILSRockySea Petro Double Separation Weighting Multiphase Flow Meter DeviceRockySea Petro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement and test equipment, which can meet the requirements of product design, development, production and service and has the only multiphase flow laboratory for Sinopec.The main products are single-screw and twin-screw oil-gas mixed pump, MFM2000 series multiphase flowmeter, LPT mul

VIEW DETAILSRockySea Petro: A Pioneer in Well Flushing and Dewaxing truck Manufacturing in China RockySea Petro specializes in producing Well Flushing truck and Well Dewaxing truck.RockySea Petro its establishment, RockySea Petro has always insisted on taking the market as the center, taking R&D as the driving force, and constantly improving product quality. Our Well Flush unit and Dewaxing unit have different types to fit various work condition and clients request.

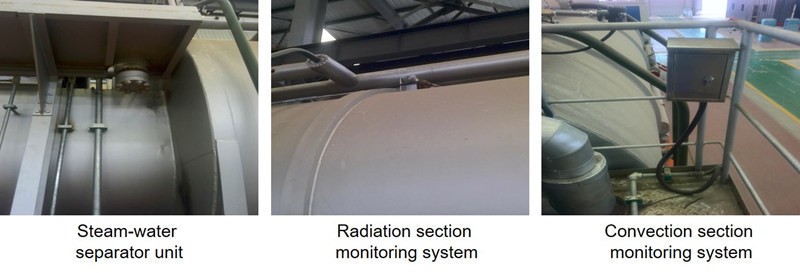

VIEW DETAILSRockySea Petro Superheated Steam Injection BoilerSupercritical Oilfield Steam Injection BoilerDesulfurization and Denitrification Oilfield Steam BoilerProduced-water Oilfield Steam GeneratorSuperheated Oilfield Steam BoilerHigh-dryness Steam Injection BoilerOilfield steam injection boiler, also known as wet steam generator, is a special steam injection equipment for heavy oil recovery in oil fields. It uses the heat generated by the combustion of gas or fuel oil to heat and vaporize water, genera

VIEW DETAILSRockySea Petro Rod PumpThe raw material of rod pump parts should be inspected after heat treatment, the mechanical properties, chemical compositions and metallographic structures must be inspected by batch. The rod pump parts should be inspected several times during the processing procedure. Some key points like the outer diameter of the plunger and the inner diameter of the pump barrel should be 100% inspected.Your Best Pump ManufacturersSealing performance tests must be carried out 100% after fini

VIEW DETAILS

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP