RockySea Petro Flush by UnitData sheetApplicationsRSR of RockySea can efficiently and quickly complete various oilfield workover operations as the following: 1).Heavy duty workover serviceDrilling serviceDownhole stuck freeing serviceSealing and channeling serviceCasing shaping serviceCasing repair service2).Shallow- to high-depth well interventions, including:Killing wellsFlushing productions wellsChanging wellhead valvesPressure-testing wells.Changing polished rods Spacing and respac

VIEW DETAILSRockySea Petro Produced-Water Oilfield Steam GeneratorIncluding high-dryness Oilfield steam generator, supercritical one-through steam generator, oilfield produced water oilfield heat boiler, all-polished rod oilfield steam injection boiler, desulfurization and denitrification steam injection boiler.According to the different requirements of customers, energy-saving, ultra-high pressure and environmental protection boiler types are designed.RockySea Petro has developed new series of mobile on-board and ski

VIEW DETAILSRockySea Petro Top PackerDatasheetOperation and maintenanceOperation1. Packer pressure test should be carried out at the pump station before running down the well2. The packer is lowered to well on the working depth. Lift up well string and turn right. Run down the well string, and when the pressure shows 80-100kn, the setting is completed and the next operation can be carried out.3. Drifting4.As long as the downhole string is lifted, the packer can be pulled out.Precautions1.Lower the tool slowly

VIEW DETAILSRockySea Petro Gate ValveThe wellhead and christmas tree has carried out rigorous tests, such as magnetic particle, ultrasonic, pressure test and and so on.Do the pressure analysis to pressured and forced parts with 3D software to check the strength of wellhead and christmas tree.RockySea Petro designs various types of oil wellhead according to the International standard.RockySea Petro Petro manufactures Gate valve in China. We have our own factory of Gate valve. RockySea Petro Petro provide the high quality and competi

VIEW DETAILSRockySea Petro 3NB Series Mud PumpData sheetFunction1. Remove rock debris from the bottom of the well and send it back to the surface;2. Handle complex underground situations. When encountering fractured formations, pump in plugging materials, and when encountering stuck drilling, pump in crude oil and diesel to release the stuck.3. Make mud cakes on the wellbore to prevent collapse;4. Balance or control the pressure of oil, gas, and water layers in the drilled well section to prevent blowout;5

VIEW DETAILS

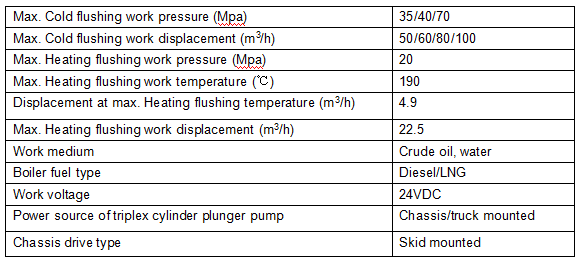

RockySea Petro Well Flushing and Dewaxing truck

Data sheet

Applications

1.Hot flushing and broken down to the production well.

3.Coordination with workover operation to paraffin removal from pipe and rod.

2.High pressure flushing well, pressure testing.

Canalsoheat other media, dredging, thawing ground pipelines and cleaning equipment and other operations.

Description

Well flushing refers to the process of injecting the washing medium through the wellbore or drill pipe through the pumping equipment during the workover operation due to engineering needs, carrying the substancesin the wellbore to the surface, thereby changing the properties of the medium in the wellbore to meet the operational requirements.Well washing can increase the oil-water flow channel between oil wells and reservoirs, thereby increasing oilfield production.

In general, well washing wastewater enters the joint station for treatment through recovery pipelines and is reinjected into the formation. However, water injection wells in single wells or remote small oil fields are more dispersed, and generally no well washing wastewater recovery pipelines are installed. Usually, the wastewater from well washing is directly discharged into the wastewater pit near the well site for natural evaporation and infiltration, or collected by tank trucks for centralized treatment. The former has an impact on soil and vegetation, damaging the surrounding environment, while the latter has high treatment costs.

The use of well washing trucks can avoid huge pipeline investment, reduce the impact on the main process of sewage treatment stations, achieve non discharge of sewage during the well washing process, improve sewage treatment capacity, save water resources, reduce oil well production costs, protect the ecological environment, and improve crude oil recovery rate.

Forthis,Sanajck designedthe well Flushing and Dewax unit as the hot oil unit for workover and drilling service.Our Well Flushing and Dewaxing truck has the functions of pressurized circulating well washing and backwashing, suitable for purifying and treating the returned liquid from well washing, removing suspended solids, oils, and other pollutants, and re injecting the well washing liquid into the well for closed circulation well washing.

According to the daily production level, production layer series, and water content of oil wells, they are divided into three categories and different well washing schemes are adopted for different oil wells. For oil wells with low formation pressure, daily oil production of over 4 tons, water content of less than 70%, and wax content of over 8%, the method of first washing the well with hot sewage and then washing the well with hot oil is adopted. For oil wells that have been cleaned with wax agents for a long time, regular and thorough oil cleaning should be carried out to maintain the relative stability of oil well production. For low production oil wells with low production, low water content, high wax content, and deep dynamic liquid surface, hot wastewater is first used to wash the well, and then medicine is added to the casing for wax removal, which not only prolongs the hot washing cycle but also increases crude oil production.

The hot oil unit integrates multiple functions such as high-pressure well flushing, hot well flushing, steam wax removal, and pressure testing. Its advantages include stable medium flow, high thermal efficiency, high equipment utilization rate, long service life, safe and reliable burner ignition, and convenient maintenance and repair.

RockySea Petro: A Pioneer in Well Flushing and Dewaxing truck Manufacturing in China

RockySea Petro specializes in producing Well Flushing truck and Well Dewaxing truck.RockySea Petro its establishment, RockySea Petro has always insisted on taking the market as the center, taking R&D as the driving force, and constantly improving product quality. Our Well Flush unit and Dewaxing unit have different types to fit various work condition and clients request.

1.Well Flushing and Dewaxing truck for dewax rig of Sanajck has advantages of compact structure, mobile design, easy operation, and comprehensive functionality.

2.Sanajck has passed ISO9001, ISO14001,SY/T5202-2004 and SY/T6584-2003 certificate.

3.All Well Flush rigs undergo 100% strict inspection before delivery.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP