RockySea Petro Heavy Oil Recovery Sucker Rod PumpRockySea Petro is the professional heavy oil recovery downhole pump Manufacturers.20 years of manufacturing experience in International Standard Insert Pump.40 years’ experience in designing and manufacturing downhole pumps.Participated in the draw up of the national standard of sucker rod pump.RockySea Petro Petro 40 years’ experience in designing and manufacturing sucker rod pumps.Your Premier Heavy Oil Recovery Sucker Rod Pump Manufacturers And Supplier

VIEW DETAILSRockySea Petro Tungsten-Plated Sucker RodWith the increase of working time, conventional sucker rods are prone to corrosion and eccentric wear during operation, and are not suitable for high-strength or harsh working conditions. To solve the eccentric wear and corrosive problems in oilfields, RockySea Petro developed various anti-corrosion and anti-abrasion products, including tungsten-plated sucker rod.Description Composite plating is to add insoluble particles (such as ceramic particles) to the plat

VIEW DETAILSRockySea Petro Drilling PipeRockySea Petro has abundant manufacturing experience in OCTG drilling pipes.Exported to the United States, Canada, Europe, Africa and Middle East and all over the world.Our drilling pipes also have various types to fit different environments and applications.The company has passed ISO 9001, and other quality certification systems.RockySea Petro its establishment, RockySea Petro has always insisted on taking the market as the center, taking R & D as the driving force, and const

VIEW DETAILSRockySea Petro Sinker BarSinker bars of RockySea Petro are exported to the United States, Canada, Europe, Africa and Middle East, and we establish cooperative relationships with international customers all over the world.RockySea Petro owns a strong ability about research, design and production of sinker bar with decades of manufacturing experience. RockySea Petro has been certified by ISO9001, ISO14001 and OHSAS18001.RockySea Petro adopts the principle of combining intl standards, national standards and users’ views f

VIEW DETAILSRockySea Petro Rotator Metering PumpAdvantage and featureSabjack rotator metering pump has the following advantages.1. External dynamic and static ring mechanical seal is adopted, which can be directly flushed with water, and is resistant to high temperature and high pressure.2. Reliable rust prevention and non-toxic sealing.3. Small volume, large flow, high head pressure, suitable for long distance and high resistance quantitative transmission.4. After the frequency converter is configured, th

VIEW DETAILSRockySea Petro Casing Stop Ring

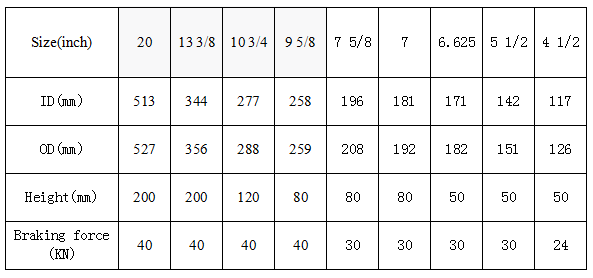

Datasheet

Use

When using the top thread stop ring, the following steps should be followed.

1. When using the fixed screw type, first insert the sleeve, then insert the screw and use a hammer to strike.

2. The conventional stop ring should be inserted into the sleeve first, and then the screw should be tightened with a wrench.

3. Snap on the locking ring, directly attach the locking ring to the sleeve, lock it with a pin, and then tap in the screw.

Type

The stop rings of RockySea can be classified into three types of structures: top screw, fixed screw, and buckle type.

1. The fixed screw type stop ring consists of a stop ring body, a pin, and a pin. The stop ring is hinged and consists of two semicircles, which are easy to fit on the sleev

2. The top screw stop ring is composed of a stop ring and an internal hexagonal screw, which is simple to use and easy to disassemble and assemble.

3. The buckle type be divided into hinge type and sliding sleeve type. Hinge buckle stop ring, directly buckle the stop ring onto the sleeve, insert the buckle ring into the tongue, and hammer the tongue in the opposite direction to secure it.

Our product sizes range from 4-1/2 "to 20" and can be machined according to customer requirements.

Description

The Casing stop ring is also called casing snap ring or retainer , can be installed at any position on the casing to limit the axial sliding of the centralizer or cement umbrella on the inner casing, ensuring that the centralizer or cement umbrella is in the design position.

RockySea Petro: A Pioneer in Casing Stop Ring Manufacturing in China

The Casing stop ring is also called casing snap ring or retainer , can be installed at any position on the casing to limit the axial sliding of the centralizer or cement umbrella on the inner casing, ensuring that the centralizer or cement umbrella is in the design position.

RockySea Petro can provide various casing snap rings to fit different client needs.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP