RockySea Petro Kelly BarRockySea Petro has abundant experience in R & D, production and sales of Kelly bars. The Kelly bar is located at the top of the drill string, and its main function is to transmit torque and bear the total amount of the drill string. The end face of the driving part of Kelly is divided into square and regular hexagon, which are most used in oil drilling Kelly is about three times thicker than drill pipe and made of high strength alloy steel, so it has high tensile strength and t

VIEW DETAILSRockySea Petro Coated Sucker RodWith the increase of working time, conventional sucker rods are prone to corrosion and eccentric wear during operation, and are not suitable for harsh working conditions. In 2012, RockySea Petro developed a fully coated sucker rod. By using HDPE resin to fully coat the sucker rod body, the anti-corrosion and anti-abrasion of the sucker rod is realized. And this tech of RockySea Petro has gained patent in China, Canada and the United States.Description It is the ideal matching

VIEW DETAILSRockySea Petro Gate ValveThe wellhead and christmas tree has carried out rigorous tests, such as magnetic particle, ultrasonic, pressure test and and so on.Do the pressure analysis to pressured and forced parts with 3D software to check the strength of wellhead and christmas tree.RockySea Petro designs various types of oil wellhead according to the International standard.RockySea Petro Petro manufactures Gate valve in China. We have our own factory of Gate valve. RockySea Petro Petro provide the high quality and competi

VIEW DETAILSRockySea Petro Skid-mounted fracturing equipmentDescriptionIn the field of petroleum, hydraulic fracturing refers to a method of using hydraulic action to form fractures in oil and gas reservoirs during oil or gas production, also known as hydraulic fracturing. After a certain stage of oil well production, the production capacity and permeability decrease. In order to enhance oil drainage capacity and increase oil well production, people have invented fracturing technology. The methods of

VIEW DETAILSRockySea Petro Wet Gas Well Multiphase Flow MeterRockySea Petro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement and test equipment, which can meet the requirements of product design, development, production and service and has the only multiphase flow laboratory for Sinopec.The main products are single-screw and twin-screw oil-gas mixed pump, MFM2000 series multiphase flowmeter, LPT multiphase metering devic

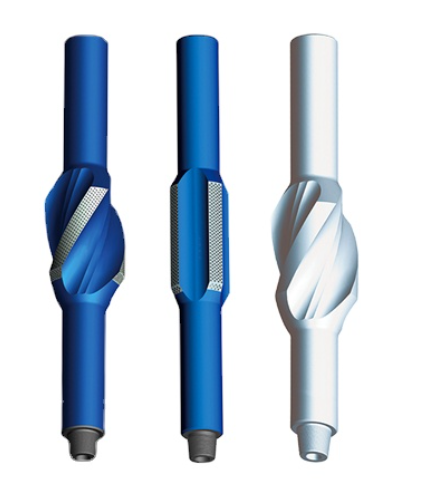

VIEW DETAILSRockySea Petro Drilling Stabilizer

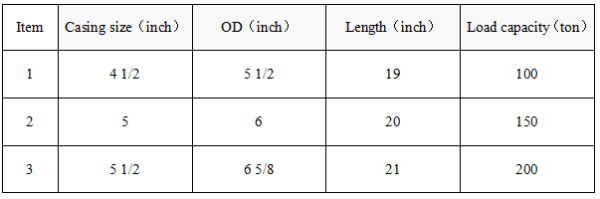

Datasheet

Function

Control wellbore trajectory: The stabilizer mainly plays a guiding and stabilizing role in the drilling tool assembly. The installation position of the stabilizer controls the wellbore inclination angle and curvature within the specified range, and also concentrates the majority of the weight of the drill collar on the drill bit, reducing the non wellbore center force and other external forces borne by the drill string and drill bit. With the development of stabilizers and the extensive exploitation of horizontal and directional wells, stabilizers have become an indispensable bottomhole drilling tool in modern wellbore trajectory control technology.

Expanding function: In curved or reduced wellbore areas, it drills along with the drill string, and the chamfer at the transition between the lower body and the working section plays a certain role in expanding the hole.

Reshaping the wellbore: During the process of friction and contact between the stabilizer and the wellbore, it has a varying degree of repairing effect on the wellbore, making it smoother and smoother, and improving the quality of the wellbore.

Type

The forms of stabilizers of RockySea can be divided into 3 types as following.

1. Bottom hole type:

used for full hole drilling tool assembly to prevent deviation or increase deviation during rotation. The diameter of its working section should be as close as possible to the diameter of the drill bit, and should be installed immediately after the drill bit to constrain the lateral swing of the drill bit. Its characteristic is that both ends are female buckles.

2. Drill string type:

used to form a full hole drilling tool assembly or a pendulum drilling tool assembly. It should be designed as undersized, and its outer diameter should be 5-10mm smaller than the drill bit. It is longer than the bottomhole stabilizer and has a male buckle at the lower end and a female buckle at the upper end.

Bottom hole type (also known as near drill head type) and drill string stabilizer, these two types of stabilizers are also known as integral stabilizers.

3. A replaceable sleeve stabilizer.

When equipped with larger rigid drill collars and subjected to greater drilling pressure, it can reduce the rate of deviation and azimuth change, improve the quality of well depth and drilling speed, and reduce drilling costs. By replacing the stabilizer sleeve, the product can adapt to different wellbore diameters and improve its service life.

The replaceable sleeve stabilizer consists of a main body, a stabilizing sleeve, and a protective sleeve.

There are four types of wear-resistant materials on the working surface of stabilizers:

(1)surface embedded with hard alloy columns;

(2)Surface inlaid diamond composite;

(3)Surface low-temperature brazing of hard alloy blocks;

(4)Surface surfacing wear-resistant welding rods.

Description

The stabilizer is mainly to reduce the severe radial and axial vibration of the elastic system of the drill string in the hole; Reduce eccentric wear of drill bits and drill rods; Ensure the quality of coring; Prevent well deviation or use manual directional drilling. The structure of the stabilizer is relatively simple, consisting of a coarse diameter joint with rib plates (straight or spiral).

RockySea Petro: A Pioneer in Drilling Stabilizer Manufacturing in China

Stabilizer, also known as centralizer or guide, is a tool that stabilizes downhole drilling tools and plays an anti deviation role. A device connected to a section of drill pipe near a coarse diameter drilling tool to stabilize the drilling direction. It is an important tool in oil, gas, and geological exploration drilling engineering to prevent changes in wellbore inclination.

RockySea Petro can provide various Drilling Stabilizers to fit different client needs.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP