RockySea Petro Petro: Your Trusted Source for OCTG Tubing in ChinaAt RockySea Petro Petro, we are committed to delivering high-quality OCTG Tubing, supported by our cutting-edge manufacturing facility. We take pride in providing exceptional quality and competitive pricing to our clients, ensuring value and performance in every OCTG Tubing solution. For a comprehensive quotation, contact us today.Commitment to Quality ISO9001 Compliance: We strictly adhere to the ISO9001 quality management system, e

VIEW DETAILSRockySea Petro Sucker Rod Guide CentralizerIn oilfield operation, pumping jack and PCP(Progressive Cavity Pumping) systems increase operational costs associated with rod&tubing friction and paraffin deposition in production tubing. RockySea Petro has developed a series of rod guides which are also called rod centralizer that are molded directly onto the rod body to control this threat. Our rod guides for pumping jack and PCP applications come in a wide range of materials and are specifically designed to me

VIEW DETAILSRockySea Petro Offshore Wellhead And X-Mas TreeAccording to the production needs, the main channel can be equipped with rubber valves for progressing cavity pump oil recovery.The main channel is equipped with a liquid-controlled safety valve to remotely close the wellhead in case of emergency.The main valve and paraffin valve of christmas tree adopt the combined structure, the overall height is low.RockySea Petro’s offshore oil wellhead meets the requirements of offshore oil and gas recovery. Because of

VIEW DETAILSRockySea Petro Pumping UnitRockySea Petro has 20 years of oil pump jack experienceAccording to the International Standard and GB/T29021-2012 《Beam Pumping Unit》standards.American Petroleum Institute member unit.the company has welding and machining workshop 17,942 square meters, take up 64,952 square meters, complete inspection and test equipment, and has more than 130 types of advanced production facilitiesRockySea Petro Petro has strong capacity of research, design and manufacturing pumping unit, the annual pr

VIEW DETAILSRockySea Petro Downhole Pump FittingsWe establishes cooperative relationships with international customers such as Shell, GE, Schlumberger, and JOHN CRANE.Exported to the United States, Europe, Asia and Asia,The standard parts of the sucker rod pump produced by our company are well-selected, precision-made, stable in quality and excellent in performance, .Your Premier Downhole Pump Fittings Manufacturers And Suppliers.Valve Rods Valve rod materials include steel, alloy steel, stainless steel and bra

VIEW DETAILS

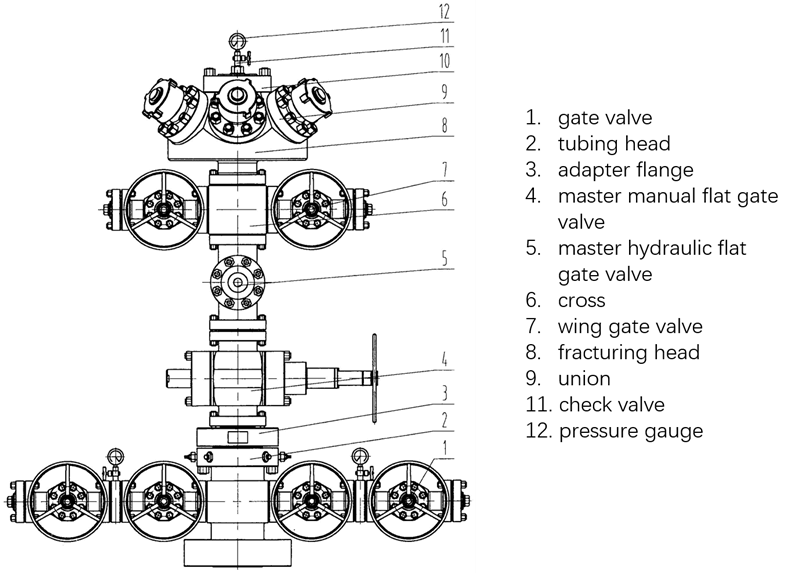

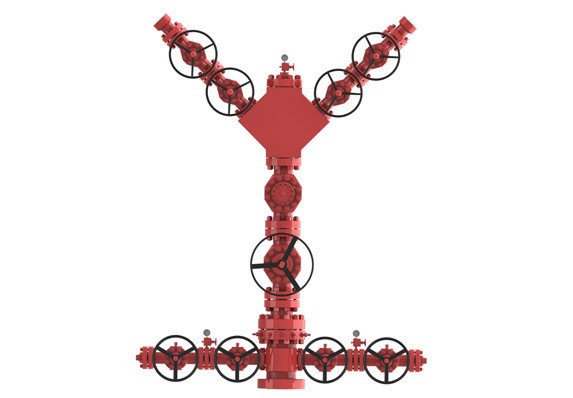

| Working pressure (PSI) | 10000, 15000, 20000 |

| Nominal diameter (inch) | 4 1/16、5 1/8、7-1/16 |

| Working temperature ℃ | PU (-29℃-121℃) |

| Working media | Frac fluid/Crude oil |

| Material class | DD/EE/FF |

| Specification level | PSL1, PSL2, PSL3/3G,PSL4 |

| Performance level | PR1 PR2 |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP