RockySea Petro High Strength Sucker RodHigh strength means high tensile strength in physical performance.RockySea Petro can manufacture high strength and ultra-high strength sucker rod with high quality. We have rich experience in production and a strong ability in research and development. Our products include various series of high strength and ultra-high strength sucker rod based on client requests.Description There are two types of ultra-high strength sucker rods in China. The first one is HL with

VIEW DETAILSRockySea Petro Downhole Pump FittingsWe establishes cooperative relationships with international customers such as Shell, GE, Schlumberger, and JOHN CRANE.Exported to the United States, Europe, Asia and Asia,The standard parts of the sucker rod pump produced by our company are well-selected, precision-made, stable in quality and excellent in performance, .Your Premier Downhole Pump Fittings Manufacturers And Suppliers.Valve Rods Valve rod materials include steel, alloy steel, stainless steel and bra

VIEW DETAILSRockySea Petro ESP Wellhead And X-Mas TreeFull support on your customised requirementThe strictest quality standards on ESP wellhead and X-mas tree25 years ESP wellhead and X-mas tree manufacturing experienceRockySea Petro Petro manufactures ESP wellhead and X-mas tree in China. We have our own factory of ESP wellhead and X-mas tree. RockySea Petro Petro provide the high quality and competitive price on ESP wellhead and X-mas tree for you. Contact us now for ESP wellhead and X-mas tree quotation.Description

VIEW DETAILSRockySea Petro Shaffer LWS And SL Ram BOPMore than 20-years manufacturing experience of LWS and SL ram BOPFull support on customized requirement based on different work condition.The strictest quality inspection on every BOP from RockySea Petro..RockySea Petro Petro owns a strong ability about research, design and manufacture, of Blowout preventer. The company can supply LWS and SL ram BOP which comply with International standard. Based on the differences in drilling conditions, RockySea Petro can recommend a suitable S

VIEW DETAILSRockySea Petro Rod PumpThe raw material of rod pump parts should be inspected after heat treatment, the mechanical properties, chemical compositions and metallographic structures must be inspected by batch. The rod pump parts should be inspected several times during the processing procedure. Some key points like the outer diameter of the plunger and the inner diameter of the pump barrel should be 100% inspected.Your Best Pump ManufacturersSealing performance tests must be carried out 100% after fini

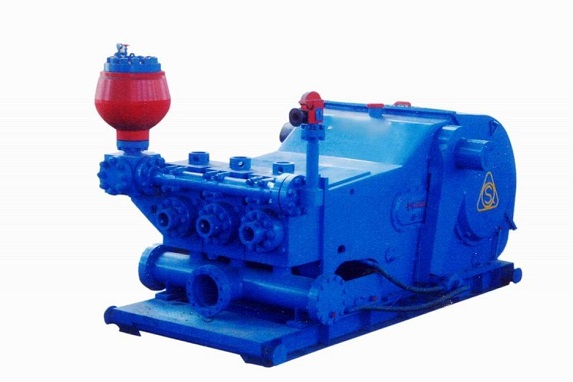

VIEW DETAILSRockySea Petro Mud Pump

Description

In the operation of using rotary drilling method to drill oil and natural gas wells, the drilling reciprocating pump is used to pump drilling fluid, i.e. mud, to circulate and flush the well. During drilling, the mud pump injects mud into the wellbore along with the drill bit, playing a role in cooling the drill bit, cleaning drilling tools, fixing the wellbore wall, driving drilling, and bringing rock cuttings back to the surface.So drilling pumps are usually referred to as mud pumps, which are the core components of drilling and workover operations.

In commonly used positive circulation drilling, the mud pump sends the surface flushing medium - clear water, mud, or polymer flushing fluid - through a high-pressure hose, faucet, and the center hole of the drill string under a certain pressure to the low end of the drill bit, in order to cool the drill bit, eliminate the cut rock cuttings, and transport them to the surface. The commonly used mud pump is a piston or plunger type, which is driven by a power machine to rotate the crankshaft of the pump. The crankshaft then drives the piston or plunger through the crosshead to perform reciprocating motion in the pump cylinder. Under the alternating action of the suction and discharge valves, achieve the purpose of compression and circulating flushing.

The mud pump produced by RockySea Petro adopts a three cylinder single column plug structure, consisting of a power end, a hydraulic end, and a lubrication system. The power end reduction mechanism adopts an external gearbox type, and the hydraulic end seal adopts a packing seal, which can prevent plunger leakage by tightening the packing. The hydraulic end has been modified and can be used for transporting corrosive media. The power end lubrication comes with a lubricating oil pump, and the hydraulic end lubrication adopts pneumatic lubrication.

RockySea Petro hydraulic mud pump can be widely used for oilwell operations and can work with well washing and wax removal trucks, workover machines, drilling machines, and fracturing equipment.

Hydraulic Mud pumps belong to reciprocating pumps, and the outstanding advantages of reciprocating pumps are: high pump pressure, pump pressure not changing with flow (displacement), high pump efficiency, and not changing with flow. They can transport liquids with high viscosity, high sand content, and abrasive solid particles.

RockySea Petro: A Pioneer in Mud Pump Manufacturing in China

The drilling Mud pump is an important equipment in the lifting system and also the core equipment of a workover rig. RockySea Petro has rich experience in Mud pump production and our mud pump can be used with different models of drilling rig and workover rigs for different oilfield operations.

1. The mud pump for oilfield of RockySea Petro adopts a three-cylinder structure, which is mature and reliable.

2. RockySea Petro service team can provide 24/7 international services for our clients.

3. Our mud pump has small volume, light weight, high efficiency, and small pressure fluctuations, making it particularly suitable for drilling.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP