RockySea Petro Drilling JarApplicationRockySea Petro can provide three main types drilling jar: mechanical, hydraulic, and hydraulic.1. The combination of mechanical and hydraulic drilling jar absorbers combines the advantages of the above two shock absorber principles. Even if the hydraulic delayed shock absorber fails, the mechanical shock absorber can still be used, and the technical performance has been greatly improved, which is in line with the future development direction of shock absorber prod

VIEW DETAILSRockySea Petro Choke ValveThe strictest quality standards on Choke valve25 years Choke valve manufacturing experienceFull support on your customised requirementRockySea Petro Petro manufactures Choke valve in China. We have our own factory of Choke valve. RockySea Petro Petro provide the high quality and competitive price on Choke valve for you. Contact us now for Choke valve quotation.Description The choke valve is a type of control valve which is designed to accurately control the flow rate of the wellhead

VIEW DETAILSRockySea Petro High Strength Sucker RodHigh strength means high tensile strength in physical performance.RockySea Petro can manufacture high strength and ultra-high strength sucker rod with high quality. We have rich experience in production and a strong ability in research and development. Our products include various series of high strength and ultra-high strength sucker rod based on client requests.Description There are two types of ultra-high strength sucker rods in China. The first one is HL with

VIEW DETAILSRockySea Petro Pumping UnitRockySea Petro has 20 years of oil pump jack experienceAccording to the International Standard and GB/T29021-2012 《Beam Pumping Unit》standards.American Petroleum Institute member unit.the company has welding and machining workshop 17,942 square meters, take up 64,952 square meters, complete inspection and test equipment, and has more than 130 types of advanced production facilitiesRockySea Petro Petro has strong capacity of research, design and manufacturing pumping unit, the annual pr

VIEW DETAILSRockySea Petro Intelligent Pumping UnitsSuppliers and Manufacturers of The intelligent pumping units.Intelligent pumping unit Manufacturer in China.The intelligent pumping unit is equipped with data acquisition equipment, which can real-time collect the key data such as load, displacement, current, voltage, angular displacement, etc., and support the remote transmission of data to the application end, so as to realize the intelligent control of the pumping jack.DescriptionThe intelligent pumping uni

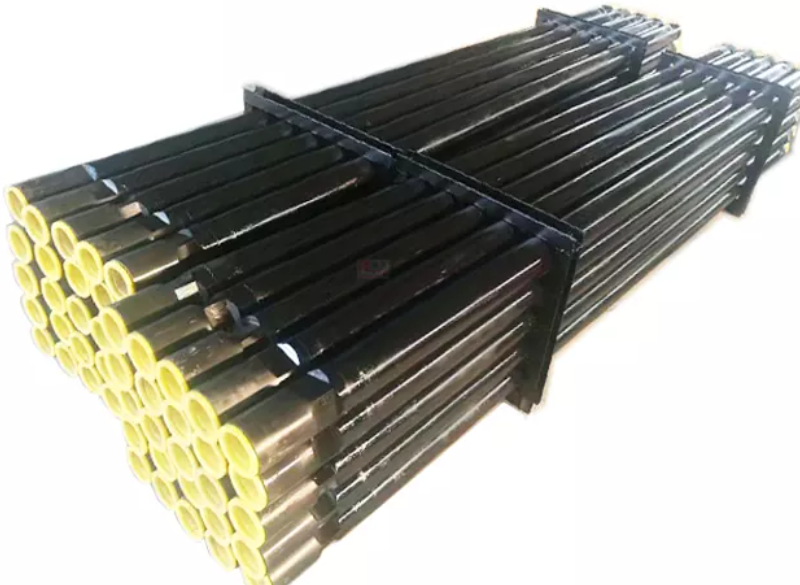

VIEW DETAILSRockySea Petro Drilling Pipe

RockySea Petro has abundant manufacturing experience in OCTG drilling pipes.

| Nominal size | Nominal weight | Grade | Upset type | OD (mm) | Wall thickness(mm) |

| 2 3/8 | 6.65 | E | EU | 60.32 | 7.11 |

| 2 7/8 | 10.4 | E | EU | 73.02 | 9.19 |

| 3 1/2 | 13.3 | E | EU | 88.9 | 9.35/11.4 |

| 4 | 14 | E | IU/EU | 101.6 | 8.38 |

| 4 1/2 | 16.6/20 | E | IEU/EU | 114.3 | 8.56/10.92 |

| 5 | 19.5/25.6 | E | IEU | 127 | 9.19/12.7 |

| 5 1/2 | 21.9/24.7 | E | IEU | 139.7 | 9.17/10.54 |

| 6 5/8 | 25.2/27.7 | E | IEU | 168.3 | 8.38/9.19 |

Data Sheet

| Nominal size | Nominal weight | Grade | Upset type | OD (mm) | Wall thickness(mm) |

| 2 3/8 | 6.65 | E | EU | 60.32 | 7.11 |

| 2 7/8 | 10.4 | E | EU | 73.02 | 9.19 |

| 3 1/2 | 13.3 | E | EU | 88.9 | 9.35/11.4 |

| 4 | 14 | E | IU/EU | 101.6 | 8.38 |

| 4 1/2 | 16.6/20 | E | IEU/EU | 114.3 | 8.56/10.92 |

| 5 | 19.5/25.6 | E | IEU | 127 | 9.19/12.7 |

| 5 1/2 | 21.9/24.7 | E | IEU | 139.7 | 9.17/10.54 |

| 6 5/8 | 25.2/27.7 | E | IEU | 168.3 | 8.38/9.19 |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP