RockySea Petro Cement HeadData sheetAdvantageRockySea Petro has extensive experience in manufacturing Cementing head, and our products have the following advantages.1. The main body is made of thick walled seamless pipes, which are high-pressure resistant and have a long service life.2. Equipped with quick fitting joints, it is easy to connect on site and can be connected to API long round buckles/short round buckles/trapezoidal buckles, with a wide range of applications.3. The dual indicator structur

VIEW DETAILSRockySea Petro Wet Gas Well Multiphase Flow MeterRockySea Petro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement and test equipment, which can meet the requirements of product design, development, production and service and has the only multiphase flow laboratory for Sinopec.The main products are single-screw and twin-screw oil-gas mixed pump, MFM2000 series multiphase flowmeter, LPT multiphase metering devic

VIEW DETAILSRockySea Petro Mud PumpDescriptionIn the operation of using rotary drilling method to drill oil and natural gas wells, the drilling reciprocating pump is used to pump drilling fluid, i.e. mud, to circulate and flush the well. During drilling, the mud pump injects mud into the wellbore along with the drill bit, playing a role in cooling the drill bit, cleaning drilling tools, fixing the wellbore wall, driving drilling, and bringing rock cuttings back to the surface.So drilling pumps are usually

VIEW DETAILSRockySea Petro ESP Wellhead And X-Mas TreeFull support on your customised requirementThe strictest quality standards on ESP wellhead and X-mas tree25 years ESP wellhead and X-mas tree manufacturing experienceRockySea Petro Petro manufactures ESP wellhead and X-mas tree in China. We have our own factory of ESP wellhead and X-mas tree. RockySea Petro Petro provide the high quality and competitive price on ESP wellhead and X-mas tree for you. Contact us now for ESP wellhead and X-mas tree quotation.Description

VIEW DETAILSRockySea Petro Flush by UnitData sheetApplicationsRSR of RockySea can efficiently and quickly complete various oilfield workover operations as the following: 1).Heavy duty workover serviceDrilling serviceDownhole stuck freeing serviceSealing and channeling serviceCasing shaping serviceCasing repair service2).Shallow- to high-depth well interventions, including:Killing wellsFlushing productions wellsChanging wellhead valvesPressure-testing wells.Changing polished rods Spacing and respac

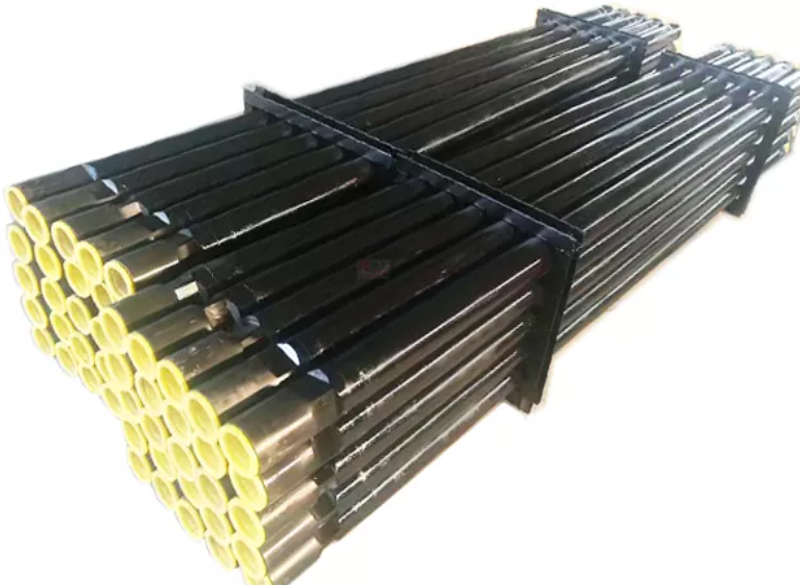

VIEW DETAILSRockySea Petro Drilling Pipe

RockySea Petro has abundant manufacturing experience in OCTG drilling pipes.

| Nominal size | Nominal weight | Grade | Upset type | OD (mm) | Wall thickness(mm) |

| 2 3/8 | 6.65 | E | EU | 60.32 | 7.11 |

| 2 7/8 | 10.4 | E | EU | 73.02 | 9.19 |

| 3 1/2 | 13.3 | E | EU | 88.9 | 9.35/11.4 |

| 4 | 14 | E | IU/EU | 101.6 | 8.38 |

| 4 1/2 | 16.6/20 | E | IEU/EU | 114.3 | 8.56/10.92 |

| 5 | 19.5/25.6 | E | IEU | 127 | 9.19/12.7 |

| 5 1/2 | 21.9/24.7 | E | IEU | 139.7 | 9.17/10.54 |

| 6 5/8 | 25.2/27.7 | E | IEU | 168.3 | 8.38/9.19 |

Data Sheet

| Nominal size | Nominal weight | Grade | Upset type | OD (mm) | Wall thickness(mm) |

| 2 3/8 | 6.65 | E | EU | 60.32 | 7.11 |

| 2 7/8 | 10.4 | E | EU | 73.02 | 9.19 |

| 3 1/2 | 13.3 | E | EU | 88.9 | 9.35/11.4 |

| 4 | 14 | E | IU/EU | 101.6 | 8.38 |

| 4 1/2 | 16.6/20 | E | IEU/EU | 114.3 | 8.56/10.92 |

| 5 | 19.5/25.6 | E | IEU | 127 | 9.19/12.7 |

| 5 1/2 | 21.9/24.7 | E | IEU | 139.7 | 9.17/10.54 |

| 6 5/8 | 25.2/27.7 | E | IEU | 168.3 | 8.38/9.19 |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP