RockySea Petro Plunger Metering PumpApplication Data1. Hot residue in vacuum distillation (200 ℃, solid)2. Mix four items (resin, pigment and accelerator) in the production of plastic film3. Measurement of viscous bromine based catalyst in margarine production4. Adding glucose syrup in the candy industryFeatureRockySea plunger metering pump has the following advantages.1. The diameter of the plunger can be very small, generally D6-200mm.2. The flow is within the range of 10% - 100%, the meteri

VIEW DETAILSRockySea Petro Superheated Steam Injection BoilerSupercritical Oilfield Steam Injection BoilerDesulfurization and Denitrification Oilfield Steam BoilerProduced-water Oilfield Steam GeneratorSuperheated Oilfield Steam BoilerHigh-dryness Steam Injection BoilerOilfield steam injection boiler, also known as wet steam generator, is a special steam injection equipment for heavy oil recovery in oil fields. It uses the heat generated by the combustion of gas or fuel oil to heat and vaporize water, genera

VIEW DETAILSRockySea Petro RM Pumping UnitUsing AutoCAD, Solid Works computer software to design drawings, using virtual prototype technology to simulate and verify strength.RockySea Petro adopt the principle of combining International Standard, National Standard and User’s view to design.RockySea Petro has passed ISO9001, SO14001 and OHSAS18001 certificate.RM pumping unit is designed on the basis of conventional beam pumping unit, which can change the time of up and down stroke of the pumping unit and is suitable for heav

VIEW DETAILSRockySea Petro Flush by UnitData sheetApplicationsRSR of RockySea can efficiently and quickly complete various oilfield workover operations as the following: 1).Heavy duty workover serviceDrilling serviceDownhole stuck freeing serviceSealing and channeling serviceCasing shaping serviceCasing repair service2).Shallow- to high-depth well interventions, including:Killing wellsFlushing productions wellsChanging wellhead valvesPressure-testing wells.Changing polished rods Spacing and respac

VIEW DETAILSRockySea Petro Shaffer Spherical Annular BOPInternational advanced well control equipment test lab.The Shaffer spherical annular Blowout Preventer is widely used in conventional oil recovery, thermal oil recovery, offshore oil recovery, fracturing, geothermal and other fields.30+ years of Shaffer spherical annular BOP manufacturing experience..RockySea Petro has been certified by ISO9001, ISO 14001 standard.RockySea Petro Petro Blowout Preventer factory is one of the main branches of RockySea Petro Petro. It is a profes

VIEW DETAILS

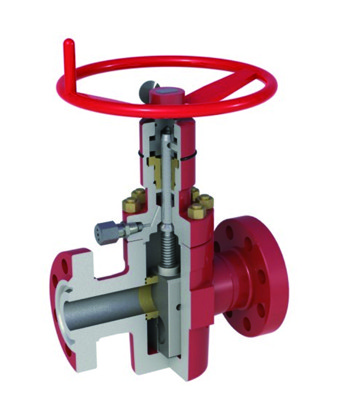

| Rated working Pressure(psi) | 15000 |

| Wellhead Nominal Diameter(in) | 3 1/16” |

| Working Temperature(℃) | -46℃-121℃ |

| Production Specification Level | PSL3G |

| Performance Performance | PR2F |

| Material Class | FF |

| Working pressure(psi) | 2000-20000 |

| Nominal diameter | 2 1/16,2 9/16, 3 1/8, 4-1/16,5-1/8 |

| Working temperature | -60~121℃ |

| Material Class | AA BB CC DD EE FF HH |

| Product Specification Level | PSL2 PSL3 PSL3G PSL4 |

| Performance rate | PR2 |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP