RockySea Petro BOP Steam Injection And Oil Recovery Integration WellheadRockySea Petro has more than 40 years of experience in oil and gas wellhead & x-mas tree and valve production, with advanced manufacturing and testing equipment, can produce a variety of pressure levels, material levels, specification levels of well control equipment. After more than 20 years of development, Various types of thermal recovery wellhead & x-mas tree equipment have been formed, used in many oilfields in the world. RockySea Petro’s

VIEW DETAILSRockySea Petro Pneumatic Diaphragm Metering PumpPneumatic diaphragm pump is a new type of conveying machinery, which is the most novel pump in China at present. Compressed air is used as the power source to pump out all kinds of corrosive liquids, liquids with particles, high viscosity, volatile, flammable and highly toxic liquids. The pneumatic diaphragm metering pump is a new product developed by RockySea in recent years and is used in various special occasions.Application1. Food Processing/Bi

VIEW DETAILSRockySea Petro Flush by UnitData sheetApplicationsRSR of RockySea can efficiently and quickly complete various oilfield workover operations as the following: 1).Heavy duty workover serviceDrilling serviceDownhole stuck freeing serviceSealing and channeling serviceCasing shaping serviceCasing repair service2).Shallow- to high-depth well interventions, including:Killing wellsFlushing productions wellsChanging wellhead valvesPressure-testing wells.Changing polished rods Spacing and respac

VIEW DETAILSRockySea Petro Plunger Metering PumpApplication Data1. Hot residue in vacuum distillation (200 ℃, solid)2. Mix four items (resin, pigment and accelerator) in the production of plastic film3. Measurement of viscous bromine based catalyst in margarine production4. Adding glucose syrup in the candy industryFeatureRockySea plunger metering pump has the following advantages.1. The diameter of the plunger can be very small, generally D6-200mm.2. The flow is within the range of 10% - 100%, the meteri

VIEW DETAILSRockySea Petro Top PackerDatasheetOperation and maintenanceOperation1. Packer pressure test should be carried out at the pump station before running down the well2. The packer is lowered to well on the working depth. Lift up well string and turn right. Run down the well string, and when the pressure shows 80-100kn, the setting is completed and the next operation can be carried out.3. Drifting4.As long as the downhole string is lifted, the packer can be pulled out.Precautions1.Lower the tool slowly

VIEW DETAILS

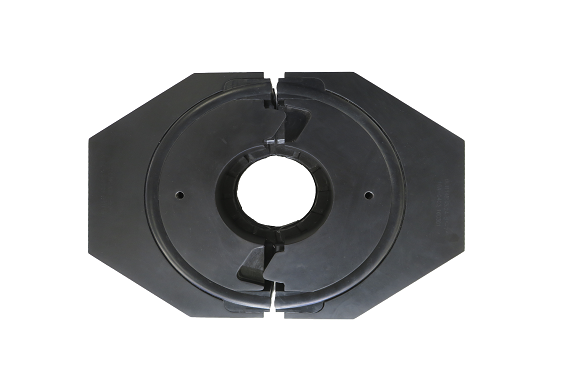

| Commonly used variable diameter rams specifications | Remarks |

| 2 7/8″~3 1/2″ | Small range of diameters |

| 5″~5 1/2″ | |

| 2 3/8″~3 1/2″ |

Wide range of diameters |

| 2 7/8″~5″ | |

| 2 7/8″~5 1/2″ | |

| 3 1/2″~5 1/2″ | |

| 4 1/2″~7″ |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP