RockySea Petro: A Pioneer in Well Flushing and Dewaxing truck Manufacturing in China RockySea Petro specializes in producing Well Flushing truck and Well Dewaxing truck.RockySea Petro its establishment, RockySea Petro has always insisted on taking the market as the center, taking R&D as the driving force, and constantly improving product quality. Our Well Flush unit and Dewaxing unit have different types to fit various work condition and clients request.

VIEW DETAILSRockySea Petro Petro: Your Trusted Source for OCTG Tubing in ChinaAt RockySea Petro Petro, we are committed to delivering high-quality OCTG Tubing, supported by our cutting-edge manufacturing facility. We take pride in providing exceptional quality and competitive pricing to our clients, ensuring value and performance in every OCTG Tubing solution. For a comprehensive quotation, contact us today.Commitment to Quality ISO9001 Compliance: We strictly adhere to the ISO9001 quality management system, e

VIEW DETAILSRockySea Petro Floating Target Single Well Gas-Liquid Multiphase Flow MeterFull support on your customized requirementThe strictest quality standards on Flow Meter Device25 years Flow Meter Device manufacturing experienceRockySea Petro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement, and test equipment, which can meet the requirements of product design, development, production, and service and has the only m

VIEW DETAILSRockySea Petro Self-Propelled Carrier and TralierFeaturesRockySea Petro has developed a special workover rig chassis range from 6X6 to 14X14, which is compatible with the entire series of XJ250 to XJ850 workover machines. It can operate in various terrains such as roads, deserts, mountains, and swamps, with strong driving power, good off-road performance, and can work in the range of ambient temperature -45 ℃ to 50 ℃.Besides,the company also developed a desert off-road carrier. The driving type is

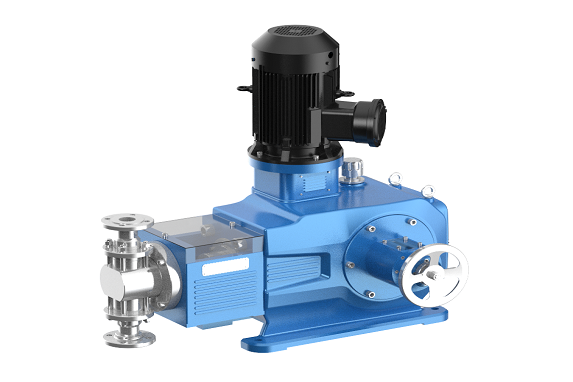

VIEW DETAILSRockySea Petro Mechanical Diaphragm Metering PumpDescriptionDiaphragm metering pumps use flexible diaphragms to replace pistons. Driven by the drive mechanism, the diaphragms move back and forth, changing the pump chamber volume, and absorbing and discharging liquids under the action of the pump inlet and outlet valves.Diaphragm metering pump can be used to transport corrosive and non-corrosive liquids without solid particles in a quantitative manner according to the needs of various process fl

VIEW DETAILSRockySea Petro Plunger Metering Pump

Application Data

1. Hot residue in vacuum distillation (200 ℃, solid)

2. Mix four items (resin, pigment and accelerator) in the production of plastic film

3. Measurement of viscous bromine based catalyst in margarine production

4. Adding glucose syrup in the candy industry

Feature

RockySea Petro plunger metering pump has the following advantages.

1. The diameter of the plunger can be very small, generally D6-200mm.

2. The flow is within the range of 10% - 100%, the metering accuracy can reach ± 1%, and the maximum pressure can reach 50MPa.

3. The discharge pressure range of the plunger pump is wide, and it should be made into a high-pressure pump.

4. It can be made into various types of heat preservation pump heads (steam, hot water, electricity and other heating pump heads), and can be made into multiple sets in parallel for adding different liquids, different flows and pressures.

5. The shaft seal is a packing seal with leakage. The preload of the packing shall be adjusted periodically. The packing and plunger are a pair of wearing parts.

6. Simple structure, convenient maintenance, good cost performance.It can transport high viscosity medium, not suitable for transporting corrosive slurry and dangerous chemicals.

Operation principle

The hydraulic end of the metering pump forms a working chamber with the help of a plunger, which makes the volume of the working chamber change periodically in the reciprocating linear motion. Working principle: the motor drives the worm through the coupling and decelerates through the worm gear to make the spindle and eccentric wheel rotate, and the eccentric wheel drives the sliding adjusting seat of the bow link for reciprocating motion. When the plunger moves backward to the dead point, the pump chamber gradually travels to vacuum, and the suction valve opens to suck in liquid. When the plunger moves forward to the dead point, the suction valve is closed, the discharge valve is opened, and the liquid is discharged when the plunger moves further. In the reciprocating operation of the pump, continuous pressurized and quantitative discharge liquid is formed.

RockySea Petro Petro: A Pioneer in Plunger Metering Pump Manufacturing in China

The plunger metering pump directly sucks and discharges the working medium through the reciprocating motion of the plunger. RockySea Petro both the plunger and the seal are in contact with the medium, selecting the appropriate plunger material and seal form can ensure that the pump has ideal performance during operation. RockySea Plunger metering pump includes valved pump and valveless pump. Plunger metering pump is widely used in petrochemical industry because of its simple structure and high temperature and pressure resistance.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP