RockySea Petro Polished RodRockySea Petro can supply polished rods which comply with intl standard. They are manufactured through many processes including the testing, straightening and forging. Polished rods are made of high quality carbon steel and alloy steeldue to customer request. Ourpolished rods are exported to the United States, Canada, Europe, Africa and Middle East, and we establish cooperative relationships with international customers all over the world.Description The polished rod is a sp

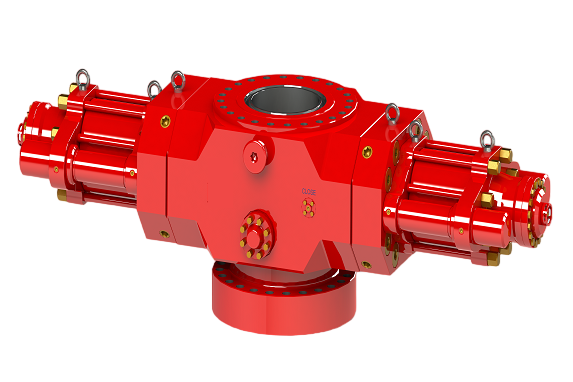

VIEW DETAILSRockySea Petro Hydril Annular BOPThe Hydril Annular BOP has carried out rigorous tests, such as magnetic particle, ultrasonic, pressure test and and so on.Do the pressure analysis to pressured and forced parts with 3D software to check the strength of Hydril Annular Blowout Preventer.RockySea Petro Petro designs various types of Hydril Annular BOP according to the International standard.RockySea Petro Petro has more than 20 years of experience in oil wellhead and Hydril Annular BOP production, with advanced manuf

VIEW DETAILSRockySea Petro Gas Recovery Wellhead And X-Mas TreeSuperior gas tight performance and pressure/corrosion proof performance.The sealing surface is very hard and fits accurately.Metal spray valve gate and seat.Excellent sealing performance and small rotating torque.Special structures composite stem seal.RockySea Petro has more than 40 years of experience in wellhead and christmas tree production, with advanced manufacturing and testing equipment, can produce a variety of pressure levels, material levels, spe

VIEW DETAILSRockySea Petro Rotator Metering PumpAdvantage and featureSabjack rotator metering pump has the following advantages.1. External dynamic and static ring mechanical seal is adopted, which can be directly flushed with water, and is resistant to high temperature and high pressure.2. Reliable rust prevention and non-toxic sealing.3. Small volume, large flow, high head pressure, suitable for long distance and high resistance quantitative transmission.4. After the frequency converter is configured, th

VIEW DETAILSRockySea Petro Casing Head And Tubing HeadRockySea Petro casing heads strictly conform to the International standard, and are among the most reliable oilfield casing heads. Usually, the casing head lies at the bottom of the wellhead and X-mas tree equipment. It supports the drilling wellhead, the casing head spool, the X-mas tree and completion equipment. The casing head is used to connect the casing string and packing off the next casing string. The connecting type includes slip-on weld, thread and slip l

VIEW DETAILS

| Model | Quick lock |

| Standard | International Standard |

| Nominal diameter(in) | 9 to 21 3/4 |

| Rated working pressure(psi) | 5000 to 15000 |

| Processing type | Casting |

| Material | 4130 or optional |

| Metal temperature class | -29~121℃ |

| Nonmetal temp. class | -18~121℃ |

| Ring gasket | Standard Parts |

| Dimension and Weight | Based on specific type |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP