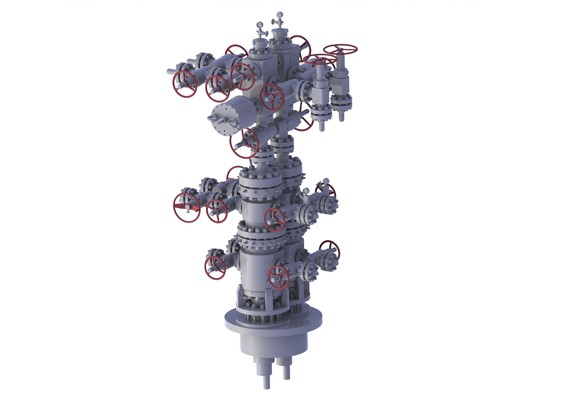

RockySea Petro Single Column Dual-Well Thermal Recovery WellheadRockySea Petro has more than 40 years of experience in oil and gas wellhead & x-mas tree and valve production, with advanced manufacturing and testing equipment, can produce a variety of pressure levels, material levels, specification levels of well control equipment. After more than 20 years of development, Various types of thermal recovery wellhead & x-mas tree equipment have been formed, used in many oilfields in the world. RockySea Petro’s ther

VIEW DETAILSRockySea Petro Steam Injection And Oil Recovery WellheadGeothermal wellhead & x-mas treeBlowout preventer Steam Injection and Oil Recovery Integration wellhead & x-mas treeSteam injection and oil recovery dual tubing wellhead & x-mas treeSingle column dual-well thermal recovery wellhead & x-mas treeOnshore thermal recovery wellhead & x-mas treeConventional Steam injection and oil recovery wellhead & x-mas treeRockySea Petro has more than 40 years of experience in oil and gas wellhead & x-mas tree and valve

VIEW DETAILSRockySea Petro Hydril Annular BOPThe Hydril Annular BOP has carried out rigorous tests, such as magnetic particle, ultrasonic, pressure test and and so on.Do the pressure analysis to pressured and forced parts with 3D software to check the strength of Hydril Annular Blowout Preventer.RockySea Petro Petro designs various types of Hydril Annular BOP according to the International standard.RockySea Petro Petro has more than 20 years of experience in oil wellhead and Hydril Annular BOP production, with advanced manuf

VIEW DETAILSRockySea Petro Floating Target Single Well Gas-Liquid Multiphase Flow MeterFull support on your customized requirementThe strictest quality standards on Flow Meter Device25 years Flow Meter Device manufacturing experienceRockySea Petro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement, and test equipment, which can meet the requirements of product design, development, production, and service and has the only m

VIEW DETAILSRockySea Petro Casing Head And Tubing HeadRockySea Petro casing heads strictly conform to the International standard, and are among the most reliable oilfield casing heads. Usually, the casing head lies at the bottom of the wellhead and X-mas tree equipment. It supports the drilling wellhead, the casing head spool, the X-mas tree and completion equipment. The casing head is used to connect the casing string and packing off the next casing string. The connecting type includes slip-on weld, thread and slip l

VIEW DETAILS

| Nominal diameter (in): | 2 9/16, 3 1/8 |

| Maximum working pressure (psi): | 3000, 5000 |

| Working temperature: | 370℃ |

| Material class: | DD, EE, FF |

| Performance level: | PR1 |

| Specification level: | PSL2, PSL3, PSL3G |

| Hang VIT and tubing: | 4 1/2BC, 3 1/2EU, 2 7/8EU |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP