RockySea Petro Supercritical Oilfield Steam Injection BoilerIntegrated Injection and Production Sucker Rod PumpThermal Recovery PackerVaccum Insluation Tubing & CasingSeries Thermal Recovery WellheadGround Steam Injection LineWater Treatment DeviceSteam Injection BoilerRockySea Petro is the thermal recovery solution supplier in China with 20 years of experience. RockySea Petro can provide customers with a complete set of thermal recovery equipment from surface steam injection boilers to underground thermal recove

VIEW DETAILSRockySea Oilfield Steam BoilerSupercritical Oilfield Steam Injection BoilerDesulfurization and Denitrification Oilfield Steam BoilerProduced-water Oilfield Steam GeneratorSuperheated Oilfield Steam BoilerHigh-dryness Steam Injection BoilerThe Oilfield Steam Boiler is a Once Through Steam Generators with a forced circulation rate of 1. The pressure of medium flow is generated from the plunger pump. This steam injection boiler is mainly used for heavy oil recovery and extra-heavy oil recovery. Oilf

VIEW DETAILSRockySea Petro Metering PumpMetering Pump is a precision pump designed to measure and dispense precise amounts of fluid. It is commonly used in various industries, including chemical, pharmaceutical, food and beverage, and oil and gas, for accurate fluid delivery and control. The Metering Pump has a pump chamber with a specific volume that fills and empties with each stroke of the pump. It uses a precise metering system to measure the exact amount of fluid being delivered, ensuring accurate dispen

VIEW DETAILSRockySea Petro Sucker Rod CouplingThe sucker rod couplings are used for connecting sucker rods, polished rods and sinker bars. Material of the couplings is high quality carbon steel or alloy steel, which are conform to and exceed the requirements of intl standards.Description According to surface of suck rod couplings, they can be divided into sucker rod couplings with smooth surface and sucker rod couplings with wrench square.Sucker rod couplings with wrench square.Sucker rod couplings with sm

VIEW DETAILSRockySea Petro Onshore Thermal Recovery WellheadRockySea Petro has more than 40 years of experience in oil and gas wellhead & x-mas tree and valve production, with advanced manufacturing and testing equipment, can produce a variety of pressure levels, material levels, specification levels of well control equipment. After more than 20 years of development, Various types of thermal recovery wellhead & x-mas tree equipment have been formed, used in many oilfields in the world. RockySea Petro’s thermal recovery wel

VIEW DETAILS

Country of Origin: China

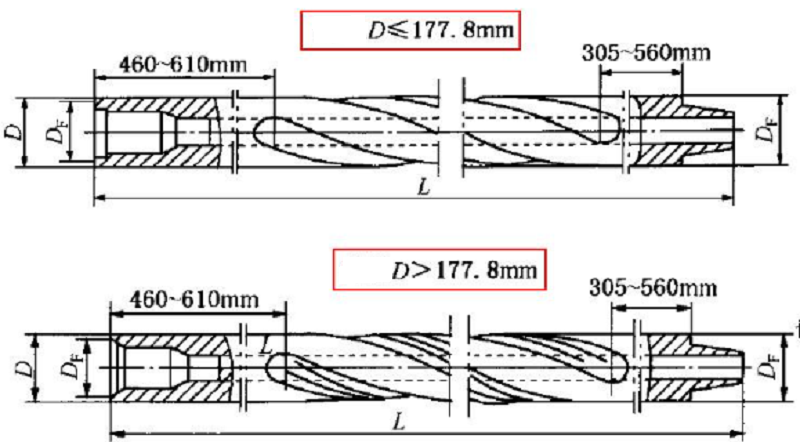

Nominal OD: 4 3/4” (4.750”) to 9” 1/2” (8.500”)

Nominal ID: 2.250” to 3” (3.000”)

Material Grade: AISI 4145H Modified

Nominal Weight: 45.00# to 144#

Nominal Wall Thickness: 3.250”

Drift Size: 2.125” to 2.875”

Manufacturing Criteria: NS-1

Relevant tool joint Parameters

Connection: NC38, Regular, REG

Bend Stress Ratio: 1.920 to 3.061

OD: 4 3/4” (4.750”) to 9”1/2” (9.500”)

ID: 2.563” to 3” (3.000”)

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP