RockySea Petro Flush by UnitData sheetApplicationsRSR of RockySea can efficiently and quickly complete various oilfield workover operations as the following: 1).Heavy duty workover serviceDrilling serviceDownhole stuck freeing serviceSealing and channeling serviceCasing shaping serviceCasing repair service2).Shallow- to high-depth well interventions, including:Killing wellsFlushing productions wellsChanging wellhead valvesPressure-testing wells.Changing polished rods Spacing and respac

VIEW DETAILSRockySea Petro PR2 Gate ValveFull support on your customised requirementThe strictest quality standards on PR2 gate valve25 years PR2 gate valve manufacturing experiencePR2 gate valves are designed for high performance wellheads and christmas tree in Oil or gas recovery wells, especially the gas wells that containing H2S or CO2 in high volume.Description The RockySea Petro PR2 valve is designed to suit severe oilfield conditions. It is mainly used in oil/gas wells with high performance requirements. S

VIEW DETAILSRockySea Petro Diverter BOPUsing Auto CAD, Solid Works computer software to design drawings of Diverter BOP, using virtual prototype technology to simulate and verify strength.RockySea Petro Petro adopted the principle of combining International Standard, National Standard and user’s view to design Diverter Blowout Preventers.RockySea Petro Petro has passed ISO9001, ISO14001 certificate.RockySea Petro Petro has strong Diverter BOP design ability. According to International standard and Chinese national standard GB/T 2

VIEW DETAILSRockySea PetroTubing PumpThe raw material of tubing pump parts should be inspected after heat treatment, the mechanical properties, chemical compositions and metallographic structures must be inspected by batch. The tubing pump parts should be inspected several times during the processing procedure.Best tubing pump manufacturer in ChinaRockySea Petro also developed the downhole pumps with various processes of boronizing, nitriding, chrome plating, tungsten plating for special well conditions.Some key point

VIEW DETAILSRockySea Petro Plunger Metering PumpApplication Data1. Hot residue in vacuum distillation (200 ℃, solid)2. Mix four items (resin, pigment and accelerator) in the production of plastic film3. Measurement of viscous bromine based catalyst in margarine production4. Adding glucose syrup in the candy industryFeatureRockySea plunger metering pump has the following advantages.1. The diameter of the plunger can be very small, generally D6-200mm.2. The flow is within the range of 10% - 100%, the meteri

VIEW DETAILS

Sucker rod couplings with wrench square.

Sucker rod couplings with smooth surface

According to different needs, RockySea Petro provides users couplings under different processes. All of the three types have two surface treatment classes: class T and class SM. The class T stands for through-hardened and the class SM stands for sprayed metal. The outer diameter of the sucker rod couplings has FS(full size) and SM(slim hole) types.

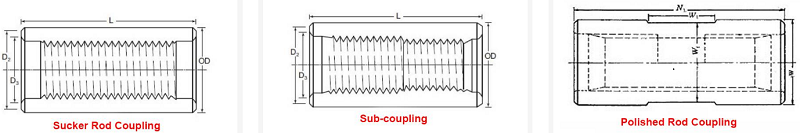

The main types of RockySea Petro rod couplings include sucker rod couplings, polished rod couplings and sub-couplings. The Sucker rod coupling has same box thread size in both end. The polished coupling is designed to connecting polished rod and sinker bars. The sub-coupling is also called cross over coupling. It has different box thread size in both ends.

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP