RockySea Petro Desulfurization And Denitrification Oilfield Steam BoilerThe utilization rate of lime can be improved and the cost of desulfurization can be saved by adopting the integration of desulfurization and dust removal.The regeneration of absorbent, desulfurization slag and precipitation are carried out outside the tower, which reduces the possibility of scaling in the tower.With NaOH desulfurizer, the circulating solution is basically NaOH aqueous solution, and there is no corrosion and blockag

VIEW DETAILSRockySea PetroTubing PumpThe raw material of tubing pump parts should be inspected after heat treatment, the mechanical properties, chemical compositions and metallographic structures must be inspected by batch. The tubing pump parts should be inspected several times during the processing procedure.Best tubing pump manufacturer in ChinaRockySea Petro also developed the downhole pumps with various processes of boronizing, nitriding, chrome plating, tungsten plating for special well conditions.Some key point

VIEW DETAILSRockySea Petro Shaffer Spherical Annular BOPInternational advanced well control equipment test lab.The Shaffer spherical annular Blowout Preventer is widely used in conventional oil recovery, thermal oil recovery, offshore oil recovery, fracturing, geothermal and other fields.30+ years of Shaffer spherical annular BOP manufacturing experience..RockySea Petro has been certified by ISO9001, ISO 14001 standard.RockySea Petro Petro Blowout Preventer factory is one of the main branches of RockySea Petro Petro. It is a profes

VIEW DETAILSRockySea Petro Frac Wellhead And Christmas TreeIn the process of oil recovery, multistage fracturing of horizontal wells is currently the most advanced technology in the world and represents the development direction of oil and gas production technology. Multistage fracturing technology is to strictly control the number, diameter, and phase of perforation in several or more horizontal sections with better reservoir along the horizontal wellbore, according to the physical properties and the character

VIEW DETAILSRockySea Petro Supercritical Oilfield Steam Injection BoilerIntegrated Injection and Production Sucker Rod PumpThermal Recovery PackerVaccum Insluation Tubing & CasingSeries Thermal Recovery WellheadGround Steam Injection LineWater Treatment DeviceSteam Injection BoilerRockySea Petro is the thermal recovery solution supplier in China with 20 years of experience. RockySea Petro can provide customers with a complete set of thermal recovery equipment from surface steam injection boilers to underground thermal recove

VIEW DETAILS

RockySea Petro Well Flushing and Dewaxing truck

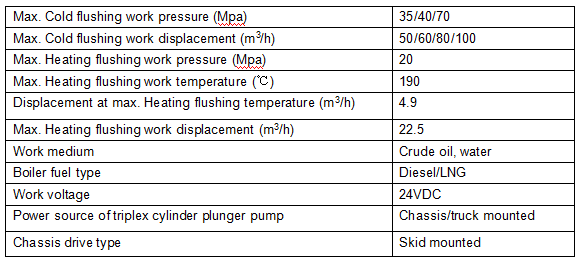

Data sheet

Applications

1.Hot flushing and broken down to the production well.

3.Coordination with workover operation to paraffin removal from pipe and rod.

2.High pressure flushing well, pressure testing.

Canalsoheat other media, dredging, thawing ground pipelines and cleaning equipment and other operations.

Description

Well flushing refers to the process of injecting the washing medium through the wellbore or drill pipe through the pumping equipment during the workover operation due to engineering needs, carrying the substancesin the wellbore to the surface, thereby changing the properties of the medium in the wellbore to meet the operational requirements.Well washing can increase the oil-water flow channel between oil wells and reservoirs, thereby increasing oilfield production.

In general, well washing wastewater enters the joint station for treatment through recovery pipelines and is reinjected into the formation. However, water injection wells in single wells or remote small oil fields are more dispersed, and generally no well washing wastewater recovery pipelines are installed. Usually, the wastewater from well washing is directly discharged into the wastewater pit near the well site for natural evaporation and infiltration, or collected by tank trucks for centralized treatment. The former has an impact on soil and vegetation, damaging the surrounding environment, while the latter has high treatment costs.

The use of well washing trucks can avoid huge pipeline investment, reduce the impact on the main process of sewage treatment stations, achieve non discharge of sewage during the well washing process, improve sewage treatment capacity, save water resources, reduce oil well production costs, protect the ecological environment, and improve crude oil recovery rate.

Forthis,Sanajck designedthe well Flushing and Dewax unit as the hot oil unit for workover and drilling service.Our Well Flushing and Dewaxing truck has the functions of pressurized circulating well washing and backwashing, suitable for purifying and treating the returned liquid from well washing, removing suspended solids, oils, and other pollutants, and re injecting the well washing liquid into the well for closed circulation well washing.

According to the daily production level, production layer series, and water content of oil wells, they are divided into three categories and different well washing schemes are adopted for different oil wells. For oil wells with low formation pressure, daily oil production of over 4 tons, water content of less than 70%, and wax content of over 8%, the method of first washing the well with hot sewage and then washing the well with hot oil is adopted. For oil wells that have been cleaned with wax agents for a long time, regular and thorough oil cleaning should be carried out to maintain the relative stability of oil well production. For low production oil wells with low production, low water content, high wax content, and deep dynamic liquid surface, hot wastewater is first used to wash the well, and then medicine is added to the casing for wax removal, which not only prolongs the hot washing cycle but also increases crude oil production.

The hot oil unit integrates multiple functions such as high-pressure well flushing, hot well flushing, steam wax removal, and pressure testing. Its advantages include stable medium flow, high thermal efficiency, high equipment utilization rate, long service life, safe and reliable burner ignition, and convenient maintenance and repair.

RockySea Petro: A Pioneer in Well Flushing and Dewaxing truck Manufacturing in China

RockySea Petro specializes in producing Well Flushing truck and Well Dewaxing truck.RockySea Petro its establishment, RockySea Petro has always insisted on taking the market as the center, taking R&D as the driving force, and constantly improving product quality. Our Well Flush unit and Dewaxing unit have different types to fit various work condition and clients request.

1.Well Flushing and Dewaxing truck for dewax rig of Sanajck has advantages of compact structure, mobile design, easy operation, and comprehensive functionality.

2.Sanajck has passed ISO9001, ISO14001,SY/T5202-2004 and SY/T6584-2003 certificate.

3.All Well Flush rigs undergo 100% strict inspection before delivery.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP