RockySea Petro Packing Seal And Spare PartThe Packing seal and spare part is widely used in conventional oil recovery, thermal oil recovery, offshore oil recovery, fracturing, geothermal and other fields..30+ years of Packing seal and spare part manufacturing experience.International advanced well control equipment test lab.RockySea Petro Petro developed a series of rubber sealing products that are compatible with the blowout preventer series products. RockySea Petro can supply different specifications and models

VIEW DETAILSRockySea Petro Diverter BOPUsing Auto CAD, Solid Works computer software to design drawings of Diverter BOP, using virtual prototype technology to simulate and verify strength.RockySea Petro Petro adopted the principle of combining International Standard, National Standard and user’s view to design Diverter Blowout Preventers.RockySea Petro Petro has passed ISO9001, ISO14001 certificate.RockySea Petro Petro has strong Diverter BOP design ability. According to International standard and Chinese national standard GB/T 2

VIEW DETAILSRockySea Petro Drilling PipeRockySea Petro has abundant manufacturing experience in OCTG drilling pipes.Exported to the United States, Canada, Europe, Africa and Middle East and all over the world.Our drilling pipes also have various types to fit different environments and applications.The company has passed ISO 9001, and other quality certification systems.RockySea Petro its establishment, RockySea Petro has always insisted on taking the market as the center, taking R & D as the driving force, and const

VIEW DETAILSRockySea Petro Heavy Oil Recovery Downhole PumpRockySea Petro is the best Heavy oil recovery pump Manufacturers for Heavy oil recovery pump wholesale.20 years of manufacturing experience in Rod Pump40 years’ experience in designing and manufacturing downhole pumps.Participated in the draw up of the national standard of downhole pump.40 years’ experience in designing and manufacturing downhole pumps.Your Premier Heavy Oil Recovery Downhole Pump Manufacturers And SuppliersDeviated Well Oil ProductionThe

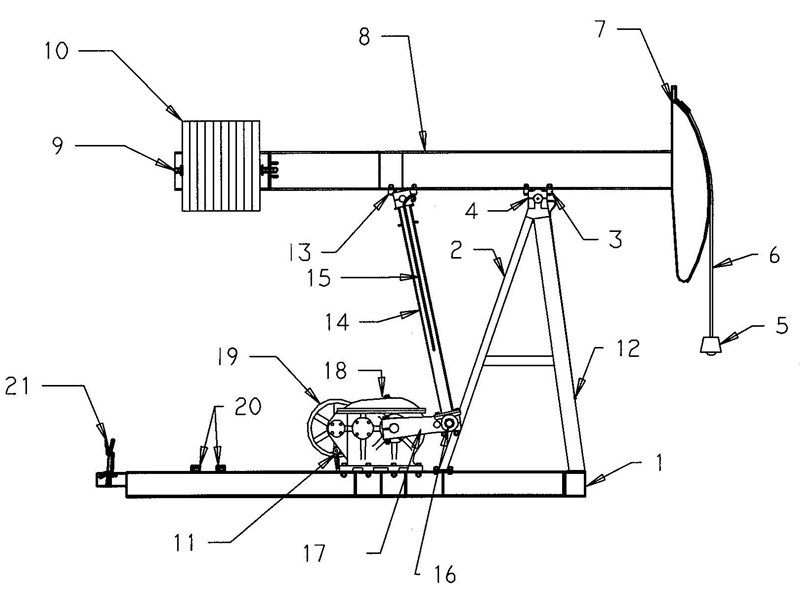

VIEW DETAILSRockySea Petro Pumping UnitRockySea Petro has 20 years of oil pump jack experienceAccording to the International Standard and GB/T29021-2012 《Beam Pumping Unit》standards.American Petroleum Institute member unit.the company has welding and machining workshop 17,942 square meters, take up 64,952 square meters, complete inspection and test equipment, and has more than 130 types of advanced production facilitiesRockySea Petro Petro has strong capacity of research, design and manufacturing pumping unit, the annual pr

VIEW DETAILS

| Model | ||||||||

| Item | B25D-67-36 | B40D-89-48 | B57D-76-48 | B57D-109-54 | B80D-133-54 | B80D-119-64 | ||

| Basic Parameters | Rated Polish Rod Capacity (lbs) | 6,700 | 8,900 | 7,600 | 10,900 | 13,300 | 11,900 | |

| Designat Stroke Length (in) | 36 | 48 | 48 | 54 | 54 | 64 | ||

| Max. Stroke Frequency (r/min) | 20 | 20 | 20 | 20 | 20 | 20 | ||

| Balanced Type | Beam Balanced | |||||||

| Crank Direction | Clockwise or Counterclockwise | |||||||

| Gear Reducer | Rated Torque(in.lbs) | 25,000 | 40,000 | 57,000 | 57,000 | 80,000 | 80,000 | |

| Model | 25D | 40D | 57D | 57D | 80D | 80D | ||

| Gear Type | Double circular arc gear reducer or Involute gear reducer | |||||||

| Reducing Ratio | 32.85 | 32.18 | 31.73 | 31.73 | 31.74 | 31.74 | ||

| Center Range (in) | 16.54 | 17.72 | 19.685 | 19.685 | 21.65 | 21.65 | ||

| Center Height (in) | 11.811 | 12.2 | 13.386 | 13.386 | 13.78 | 13.78 | ||

| Oil Storage quantity(U.S. Gal) | 8 | 9 | 12 | 12 | 16 | 16 | ||

| Lubricant | 20# Gear lubricant in winter,200# Gear lubricant in summer | |||||||

| Sheave Diameter(in) | 20″ | 20″ | 25″ | 25″ | 25″ | 25″ | ||

| Sheave groove type | 2B | 3B | 3B | 3B | 3B | 3B | ||

| Balance Assembly | Weight of Cranks (Lbs) | 115×2 | 211×2 | 211×2 | 211×2 | 211×2 | 213×2 | |

| Wrist Pin bore Positions (in) | stroke 1 | 12.01 | 17.72 | 17.72 | 17.72 | 17.72 | 18.11 | |

| stroke 2 | 12.01 | 17.72 | 17.72 | 17.72 | 17.72 | 18.11 | ||

| stroke 3 | 7.99 | |||||||

| stroke 4 | 7.99 | |||||||

| Distance between equalizer and center bearing, in | stroke 1 | 26.65 | 45.28 | 45.28 | 45.28 | 45.28 | 41.93 | |

| stroke 2 | 32.68 | 58.27 | 58.27 | 58.27 | 58.27 | 54.92 | ||

| stroke 3 | 26.65 | |||||||

| stroke 4 | 32.68 | |||||||

| Wireline | Type | 16 6×37+IWR-1770 | 22 6×37+IWR-1770 | 22 6×37+IWR-1770 | 22 6×37+IWR-1770 | 22 6×37+IWR-1770 | 22 6×37+IWR-1770 | |

| Length, in | 103 | 163.5 | 169.3 | 176 | 176 | 193 | ||

| Other | Overall Dimensions L*W*H (in) | 148×75×120 | 209×82×142 | 211×82×142 | 223×87×151 | 223×87×151 | 220×87×155 | |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP