RockySea Petro Pneumatic Diaphragm Metering PumpPneumatic diaphragm pump is a new type of conveying machinery, which is the most novel pump in China at present. Compressed air is used as the power source to pump out all kinds of corrosive liquids, liquids with particles, high viscosity, volatile, flammable and highly toxic liquids. The pneumatic diaphragm metering pump is a new product developed by RockySea in recent years and is used in various special occasions.Application1. Food Processing/Bi

VIEW DETAILSRockySea Petro Drilling PipeRockySea Petro has abundant manufacturing experience in OCTG drilling pipes.Exported to the United States, Canada, Europe, Africa and Middle East and all over the world.Our drilling pipes also have various types to fit different environments and applications.The company has passed ISO 9001, and other quality certification systems.RockySea Petro its establishment, RockySea Petro has always insisted on taking the market as the center, taking R & D as the driving force, and const

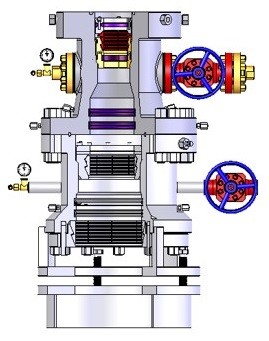

VIEW DETAILSRockySea Petro Tertiary Oil RecoveryFull support on your customised requirementThe strictest quality standards on Oilfield steam boiler25 years Oilfield steam boiler manufacturing experienceRockySea Petro Petro manufactures Oilfield steam boiler in China. We have our own factory of Oilfield steam boiler. RockySea Petro Petro provide the high quality and competitive price on Oilfield steam boiler for you. Contact us now for Oilfield steam boiler quotation.Description Oilfield steam boiler working fluid (water

VIEW DETAILSRockySea Petro: A Pioneer in Well Flushing and Dewaxing truck Manufacturing in China RockySea Petro specializes in producing Well Flushing truck and Well Dewaxing truck.RockySea Petro its establishment, RockySea Petro has always insisted on taking the market as the center, taking R&D as the driving force, and constantly improving product quality. Our Well Flush unit and Dewaxing unit have different types to fit various work condition and clients request.

VIEW DETAILSRockySea Petro Self-Tensioning Guy-Wire Workover RigFeaturesA workover rig with guy-line is a double drum workover rig that installs wind loaded guy-wires on the main engine.There is no need to install wind loaded guy-wires with ground anchors, which greatly improves the efficiency of workover operations, reduces operating costs and labor intensity.Also it has features as the following:(1) Suitable for small well site operations, reducing the operation area of the entire workover rig.(2) All te

VIEW DETAILS

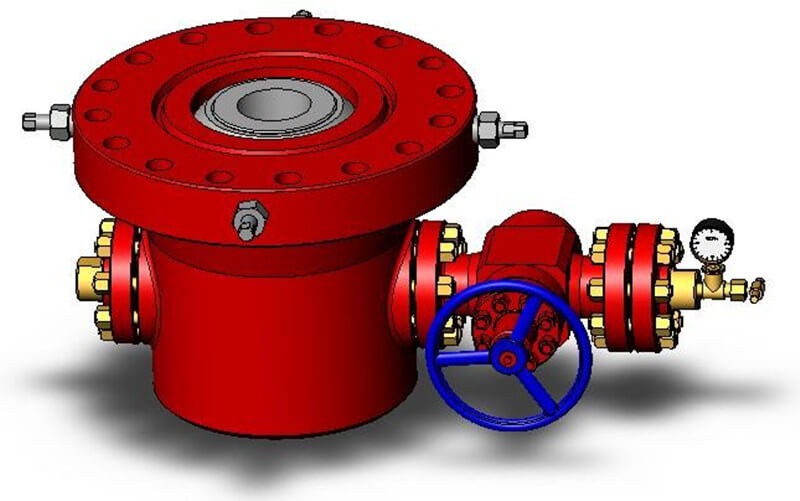

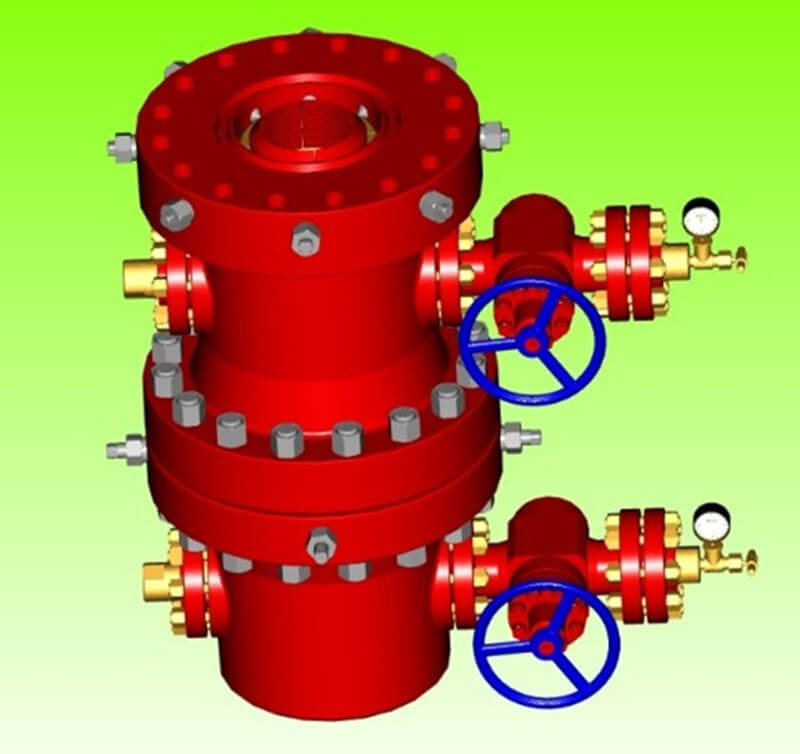

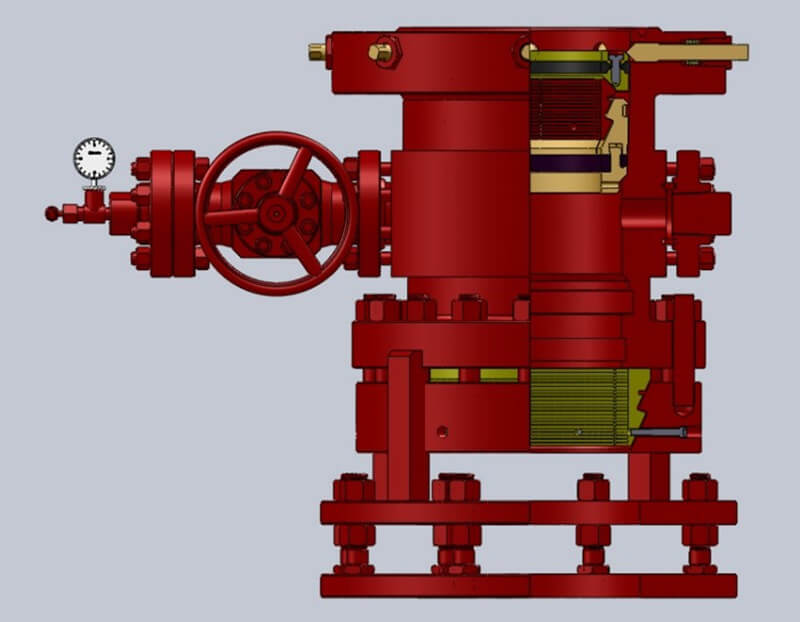

Parameters:

| Rated WP | 21MPa、35MPa 、70MPa 、105MPa |

| PSL | PSL1、PSL2、PSL3、PSL3G、PSL4 |

| PR | PR1 |

| TC | P、U、L |

| MC | AA、BB、CC、DD、EE、FF |

| Working pressure (PSI) | 2000, 3000, 5000,10000,15000,20000 |

| Nominal diameter (inch) | 2-1/16、2-9/16、3-1/8、4-1/16 |

| Working temperature ℃ | K,LU ,X,Y(-60℃-370℃) |

| Working media | Oil/Gas |

| Material class | AA/BB/CC/DD/EE/FF/HH |

| Specification level | PSL1/PSL2, PSL3/3G, PSL4 |

| Performance level | PR1 PR2 |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP