RockySea Petro Inclined Well Sucker Rod PumpFull support on your customised requirementThe strictest quality standards on Inclined well sucker rod pump25 years Inclined well sucker rod pump manufacturing experienceRockySea Petro Petro manufactures Inclined well sucker rod pump in China. We have our own factory of Inclined well sucker rod pump. RockySea Petro Petro provide the high quality and competitive price on Inclined well sucker rod pump for you. Contact us now for Inclined well sucker rod pump quotation.Descri

VIEW DETAILSRockySea Petro Cement HeadData sheetAdvantageRockySea Petro has extensive experience in manufacturing Cementing head, and our products have the following advantages.1. The main body is made of thick walled seamless pipes, which are high-pressure resistant and have a long service life.2. Equipped with quick fitting joints, it is easy to connect on site and can be connected to API long round buckles/short round buckles/trapezoidal buckles, with a wide range of applications.3. The dual indicator structur

VIEW DETAILSRockySea Petro Frac Wellhead And Christmas TreeIn the process of oil recovery, multistage fracturing of horizontal wells is currently the most advanced technology in the world and represents the development direction of oil and gas production technology. Multistage fracturing technology is to strictly control the number, diameter, and phase of perforation in several or more horizontal sections with better reservoir along the horizontal wellbore, according to the physical properties and the character

VIEW DETAILSRockySea Petro Packing Seal And Spare PartThe Packing seal and spare part is widely used in conventional oil recovery, thermal oil recovery, offshore oil recovery, fracturing, geothermal and other fields..30+ years of Packing seal and spare part manufacturing experience.International advanced well control equipment test lab.RockySea Petro Petro developed a series of rubber sealing products that are compatible with the blowout preventer series products. RockySea Petro can supply different specifications and models

VIEW DETAILSRockySea Petro Wet Gas Well Multiphase Flow MeterRockySea Petro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement and test equipment, which can meet the requirements of product design, development, production and service and has the only multiphase flow laboratory for Sinopec.The main products are single-screw and twin-screw oil-gas mixed pump, MFM2000 series multiphase flowmeter, LPT multiphase metering devic

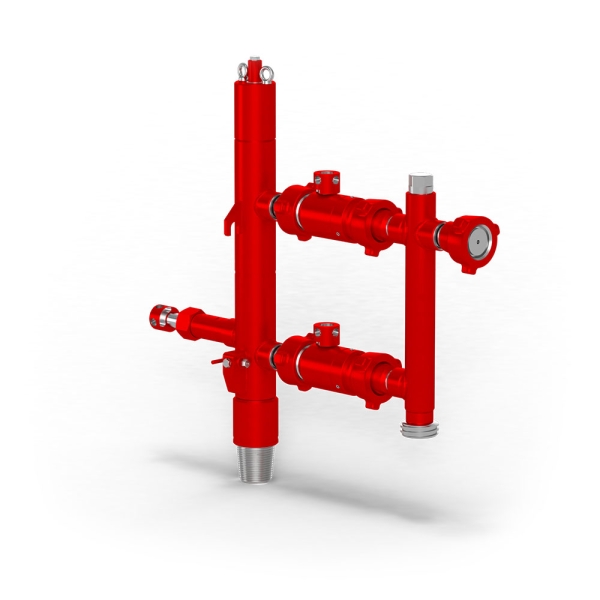

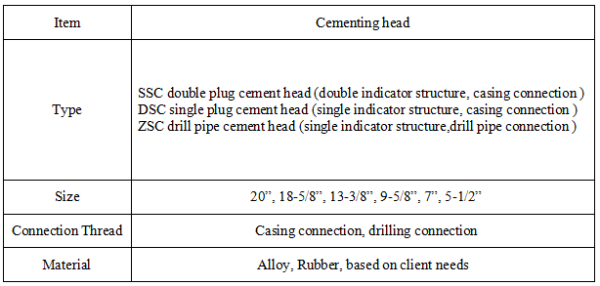

VIEW DETAILSRockySea Petro Cement Head

Data sheet

Advantage

RockySea Petro has extensive experience in manufacturing Cementing head, and our products have the following advantages.

1. The main body is made of thick walled seamless pipes, which are high-pressure resistant and have a long service life.

2. Equipped with quick fitting joints, it is easy to connect on site and can be connected to API long round buckles/short round buckles/trapezoidal buckles, with a wide range of applications.

3. The dual indicator structure accurately displays the passage of the rubber plug, making it easy for operators to make judgments.

4. The double balance pipe structure ensures that the pressure on both ends of the rubber plug is the same when using the lower interface for cementing operations, eliminating the impact of negative pressure suction on the stopper pin and making it easy to open the stopper pin.

5. The top cover and union nuts adopt large pitch trapezoidal threads, making disassembly and assembly convenient.

Structure

Mainly including cement head cylinder, top cover, plug valve, balance pipe, indicator, union interface, quick fitting joint, spiral stopper pin.

Principle

When multiple cement trucks work together, the cement head is pre filled with rubber plugs for cement injection, including upper and lower rubber plugs. Before injecting cement slurry, first put in the lower rubber plug. After the predetermined amount of cement slurry is injected, put in the upper rubber plug, and then replace it with mud or water to lower the upper rubber plug. The lower rubber plug is blocked by the support ring, and the partition in the center hole is broken until all the cement slurry is squeezed out of the casing. When the upper and lower rubber plugs collide, the liquid channel is blocked, and the pump pressure suddenly increases. The cement injection operation ends. After the cement injection is completed, close the gate leading to the outside of the cement head and remove the connecting pipeline. Wait for 12 hours to solidify, then use logging to detect the return height, and after waiting for 48 hours, perform pressure testing to check the quality of cementing.

Description

Cement head is a specialized tool used for injecting mud and releasing rubber plugs. It is a device installed at the top of the casing during cementing. The cement head can be equipped with one or two rubber plugs at the same time, and the double plug cement head can be used for conventional double plug cementing or continuous two-stage cementing operations.

RockySea Petro: A Pioneer in Cement Head Manufacturing in China

Cement head refers to the cementing device installed at the top of the casing to connect the casing and surface manifold during cementing and injection. The cement head can be used to complete operations such as circulation, injection of isolation fluid, injection of mud, release of rubber plugs, and slurry replacement, making it the main hub of the surface manifold and wellhead for cementing operations.

RockySea Petro can provide various cement head to fit different client needs.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP