RockySea Petro Polished RodRockySea Petro can supply polished rods which comply with intl standard. They are manufactured through many processes including the testing, straightening and forging. Polished rods are made of high quality carbon steel and alloy steeldue to customer request. Ourpolished rods are exported to the United States, Canada, Europe, Africa and Middle East, and we establish cooperative relationships with international customers all over the world.Description The polished rod is a sp

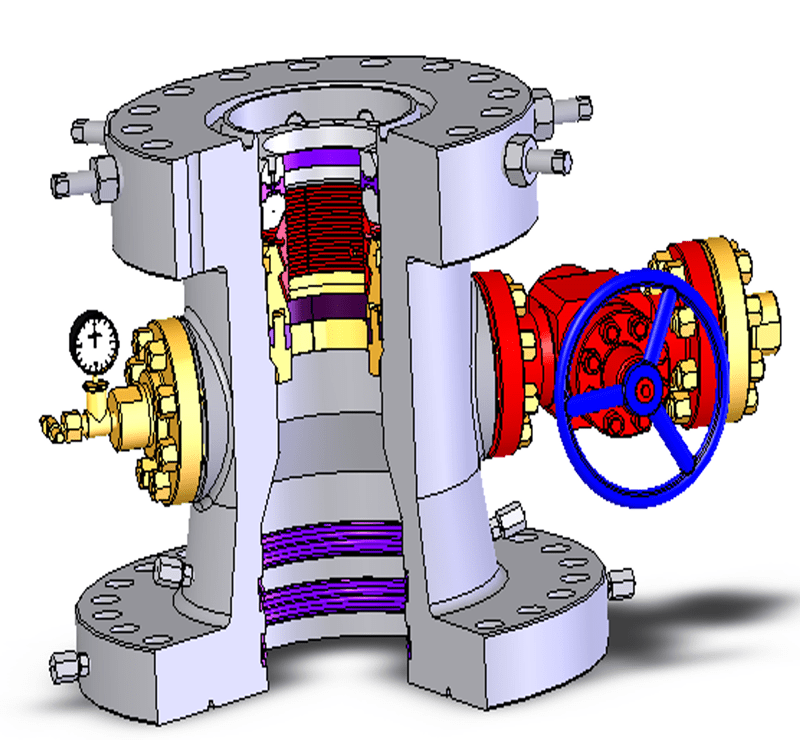

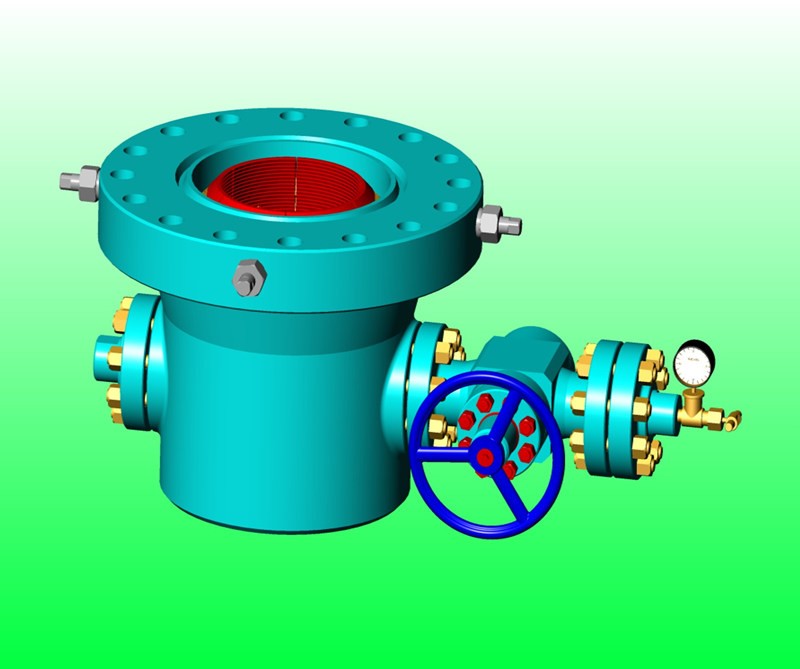

VIEW DETAILSRockySea Petro Offshore Wellhead And X-Mas TreeAccording to the production needs, the main channel can be equipped with rubber valves for progressing cavity pump oil recovery.The main channel is equipped with a liquid-controlled safety valve to remotely close the wellhead in case of emergency.The main valve and paraffin valve of christmas tree adopt the combined structure, the overall height is low.RockySea Petro’s offshore oil wellhead meets the requirements of offshore oil and gas recovery. Because of

VIEW DETAILSRockySea Petro Self-Propelled Carrier and TralierFeaturesRockySea Petro has developed a special workover rig chassis range from 6X6 to 14X14, which is compatible with the entire series of XJ250 to XJ850 workover machines. It can operate in various terrains such as roads, deserts, mountains, and swamps, with strong driving power, good off-road performance, and can work in the range of ambient temperature -45 ℃ to 50 ℃.Besides,the company also developed a desert off-road carrier. The driving type is

VIEW DETAILSRockySea Petro Large Displacement Tubing PumpNote: if our client needs different specifications and models of special oil well pump, we can also design and manufacture according to the parameters and requirements provided by the client.These special oil well pumps have novel structure, reliable performance, superior pump efficiency, and long service life, and have been widely used in various oilfields.RockySea Petro has developed a series of special oil well pumps suitable for different well conditions.Bas

VIEW DETAILSRockySea Petro Onshore Thermal Recovery WellheadRockySea Petro has more than 40 years of experience in oil and gas wellhead & x-mas tree and valve production, with advanced manufacturing and testing equipment, can produce a variety of pressure levels, material levels, specification levels of well control equipment. After more than 20 years of development, Various types of thermal recovery wellhead & x-mas tree equipment have been formed, used in many oilfields in the world. RockySea Petro’s thermal recovery wel

VIEW DETAILS

| Model Parameter | KY65-21, KY65-35, KY80-21/35 |

| Working pressure (PSI) | 2000, 3000, 5000 |

| Nominal diameter (inch) | 2-9/16,3-1/8 |

| Top flange of tubing head | 7-1/16“~13-5/8” |

| Bottom flange of tubing head | 7-1/16“~13-5/8” |

| Working temperature ℃ | -29℃-121℃ |

| Working media | Crude oil |

| Material class | BB/CC/DD/EE/FF |

| Specification level | PSL1,PSL2,PSL3 |

| Performance level | PR1 |

1 Casing Spools

C-22 casing spools feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

Features a 45° landing shoulder capable of supporting maximum casing loads.

Prevents test plugs from wedging under pressure.

Line Pipe Outlets.

Studded Side Outlets.

C-21 and C-22 slip-type casing hangers.

Mandrel style casing hangers.

Additional sizes available upon request.

Available in C-29 profile (Available upon request).

C-22-BP casing spools are supplied with (2) lock screws for wear bushing retention.

C-22-L and C-29-L casing spools are supplied with a full set of lock screws for mandrel casing hanger and packoff retention (Available upon request)

PE/BG bottom, for use with PE secondary seal bushing (Standard).

HPE bottom, for use with HPE secondary seal bushing for high pressure applications (Available upon request).

2 Casing Heads

C-22 casing heads feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

Features a 45° landing shoulder capable of supporting maximum loads

Prevents test plugs from wedging under pressure

Line Pipe Outlets

Studded Side Outlets

C-21 and C-22 slip-type casing hangers

Mandrel style casing hangers

Additional sizes available upon request

Available in C-29 profile (Available upon request)

C-22-BP casing heads are supplied with lock screws for wear bushing retention

C-22-L and C-29-L casing heads are supplied with a full set of lock screws for mandrel casing hanger and packoff retention (Available upon request)

Slip-on weld

Slip-on weld with O-ring

Threaded

3 Tubing Spools

Tubing heads feature a versatile straight bore design for single and multiple completions. This design accepts all TC series tubing hangers and easily converts from a single completion to multiple completions with the addition and alignment pin(s). The tubing heads are manufactured in API 6A low alloy steel or stainless steel.

Basic Parameters

Nominal size of top flange (in):

7-1/16 Top flange.

Nominal size of bottom flange (in):

7-1/16, 11, 13-5/8.

Bottom flange working pressure (PSI):

2M, 3M, 5M, 10M, 15M, 20M.

Nominal size of side exit (in):

2-1/16, 2-9/16.

Features a 45° landing shoulder capable of supporting maximum loads.

Line Pipe Outlets

Studded Side Outlets

WTCM tubing heads accept a wide variety of tubing hanger styles including mandrel and wrap-around.

PE/BG bottom, for use with PE secondary seal bushing (Standard).

HPE bottom, for use with HPE secondary seal bushing for high pressure applications (Available upon request).

Additional sizes available upon request.

Available with ET (Integral) style lock screws.

Flanged top Tubing Heads available with slip-on weld or threaded bottoms.

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP