RockySea Petro Superheated Steam Injection BoilerSupercritical Oilfield Steam Injection BoilerDesulfurization and Denitrification Oilfield Steam BoilerProduced-water Oilfield Steam GeneratorSuperheated Oilfield Steam BoilerHigh-dryness Steam Injection BoilerOilfield steam injection boiler, also known as wet steam generator, is a special steam injection equipment for heavy oil recovery in oil fields. It uses the heat generated by the combustion of gas or fuel oil to heat and vaporize water, genera

VIEW DETAILSRockySea Petro Drilling PipeRockySea Petro has abundant manufacturing experience in OCTG drilling pipes.Exported to the United States, Canada, Europe, Africa and Middle East and all over the world.Our drilling pipes also have various types to fit different environments and applications.The company has passed ISO 9001, and other quality certification systems.RockySea Petro its establishment, RockySea Petro has always insisted on taking the market as the center, taking R & D as the driving force, and const

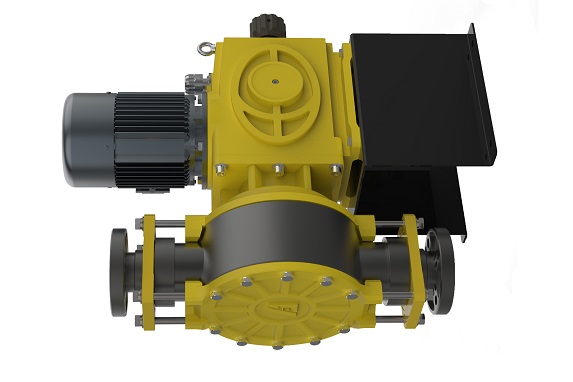

VIEW DETAILSRockySea Petro Mud PumpDescriptionIn the operation of using rotary drilling method to drill oil and natural gas wells, the drilling reciprocating pump is used to pump drilling fluid, i.e. mud, to circulate and flush the well. During drilling, the mud pump injects mud into the wellbore along with the drill bit, playing a role in cooling the drill bit, cleaning drilling tools, fixing the wellbore wall, driving drilling, and bringing rock cuttings back to the surface.So drilling pumps are usually

VIEW DETAILSRockySea Petro Common Sucker RodRockySea Petro can supply common sucker rods and pony rods which comply with intl standard. These sucker rods also have various types to fit different environments and applications. They are manufactured through many processes including the testing, straightening and forging. Sucker rods of RockySea Petro are made of high quality carbon steel and alloy steeldue to customer request. Oursucker rods are exported to the United States, Canada, Europe, Africa and Middle East, and we esta

VIEW DETAILSRockySea Petro ESP Wellhead And X-Mas TreeFull support on your customised requirementThe strictest quality standards on ESP wellhead and X-mas tree25 years ESP wellhead and X-mas tree manufacturing experienceRockySea Petro Petro manufactures ESP wellhead and X-mas tree in China. We have our own factory of ESP wellhead and X-mas tree. RockySea Petro Petro provide the high quality and competitive price on ESP wellhead and X-mas tree for you. Contact us now for ESP wellhead and X-mas tree quotation.Description

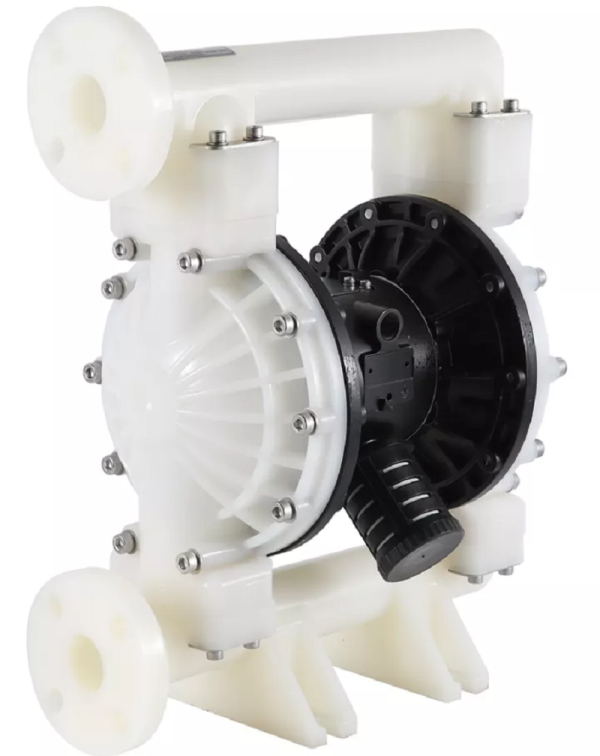

VIEW DETAILSRockySea Petro Pneumatic Diaphragm Metering Pump

Pneumatic diaphragm pump is a new type of conveying machinery, which is the most novel pump in China at present. Compressed air is used as the power source to pump out all kinds of corrosive liquids, liquids with particles, high viscosity, volatile, flammable and highly toxic liquids. The pneumatic diaphragm metering pump is a new product developed by RockySea in recent years and is used in various special occasions.

Application

1. Food Processing/Biological Hygiene/Pharmaceutical

2. Chemical Petroleum

3. Ceramic paint

4. Wastewater treatment

5. Chemical buildings/public facilities

6. Automotive Plating & Polishing

Feature

The Pneumatic diaphragm metering pump of RockySea has the following advantages.

1. Suitable for medium and high viscosity fluids.

2. Applicable to places with harsh environment, such as construction sites

3. In the treatment of hazardous and corrosive materials, the diaphragm pump can completely isolate the materials from the outside world.

4. Reliable and low cost pneumatic pump in flammable and explosive environment.

5. The pneumatic diaphragm pump is small in size and easy to move, does not need a foundation, occupies a very small area, and is simple and economical to install.

6. It can be used to transport and measure fluid with unstable chemical properties, such as photosensitive materials, flocculating liquid, etc.

Working principle

The pneumatic diaphragm metering pump is one kind of positive displacement pump whose volume changes due to the reciprocating deformation of the diaphragm. Its working principle is similar to that of a plunger pump

Two symmetrical working chambers of the pump are respectively equipped with an elastic diaphragm. The linkage links the two diaphragms together. After the compressed air enters the valve from the intake head of the pump, it pushes the diaphragms in the two working chambers to drive the two diaphragms connected by the linkage to move synchronously. At the same time, the gas in the other working chamber is discharged from the back of the diaphragm outside the pump.

Once the end of the journey is reached, the valve distribution mechanism automatically introduces compressed air into another working chamber to push the diaphragm to move in the opposite direction, thus forming a synchronous reciprocating motion of the two diaphragms. Each working chamber is equipped with two one-way ball valves. The reciprocating movement of the diaphragm changes the volume of the working chamber, forcing the two one-way ball valves to open and close alternately, thus continuously absorbing and discharging liquid.

RockySea Petro: A Pioneer in Pneumatic Diaphragm Metering Pump Manufacturing in China

Pneumatic diaphragm pump is a new type of conveying machinery, which is the most novel pump in China at present. Compressed air is used as the power source to pump out all kinds of corrosive liquids, liquids with particles, high viscosity, volatile, flammable and highly toxic liquids. The pneumatic diaphragm metering pump is a new product developed by RockySea in recent years and is used in various special occasions.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP