RockySea Petro Hydraulic Diaphragm Metering PumpRockySea Petro Petro: A Pioneer in Hydraulic Diaphragm Metering Pump Manufacturing in ChinaHydraulic diaphragm metering pump, one kind of plunger diaphragm metering pump, is a metering pump designed by combining the characteristics of plunger metering pump and diaphragm metering pump. The contact part between the metering pump and the metered medium is a diaphragm, while the driving part is a hydraulic plunger.FeatureThe hydraulic diaphragm metering

VIEW DETAILSRockySea Petro BOP Steam Injection And Oil Recovery Integration WellheadRockySea Petro has more than 40 years of experience in oil and gas wellhead & x-mas tree and valve production, with advanced manufacturing and testing equipment, can produce a variety of pressure levels, material levels, specification levels of well control equipment. After more than 20 years of development, Various types of thermal recovery wellhead & x-mas tree equipment have been formed, used in many oilfields in the world. RockySea Petro’s

VIEW DETAILSRockySea Petro Superheated Steam Injection BoilerSupercritical Oilfield Steam Injection BoilerDesulfurization and Denitrification Oilfield Steam BoilerProduced-water Oilfield Steam GeneratorSuperheated Oilfield Steam BoilerHigh-dryness Steam Injection BoilerOilfield steam injection boiler, also known as wet steam generator, is a special steam injection equipment for heavy oil recovery in oil fields. It uses the heat generated by the combustion of gas or fuel oil to heat and vaporize water, genera

VIEW DETAILSRockySea Petro High Strength Sucker RodHigh strength means high tensile strength in physical performance.RockySea Petro can manufacture high strength and ultra-high strength sucker rod with high quality. We have rich experience in production and a strong ability in research and development. Our products include various series of high strength and ultra-high strength sucker rod based on client requests.Description There are two types of ultra-high strength sucker rods in China. The first one is HL with

VIEW DETAILSRockySea Petro Water Injection Wellhead And Christmas TreeAccording to casing and well condition, Water Injection Wells can be divided into large casing well, normal well and small diameter well.According to the pipe string structure Water Injection Wells can be divided into support type and suspension type.According to their functions, water Injection wells are divided into stratified injection Wells and general injection wells.In the process of oilfield development, special water injection Wells a

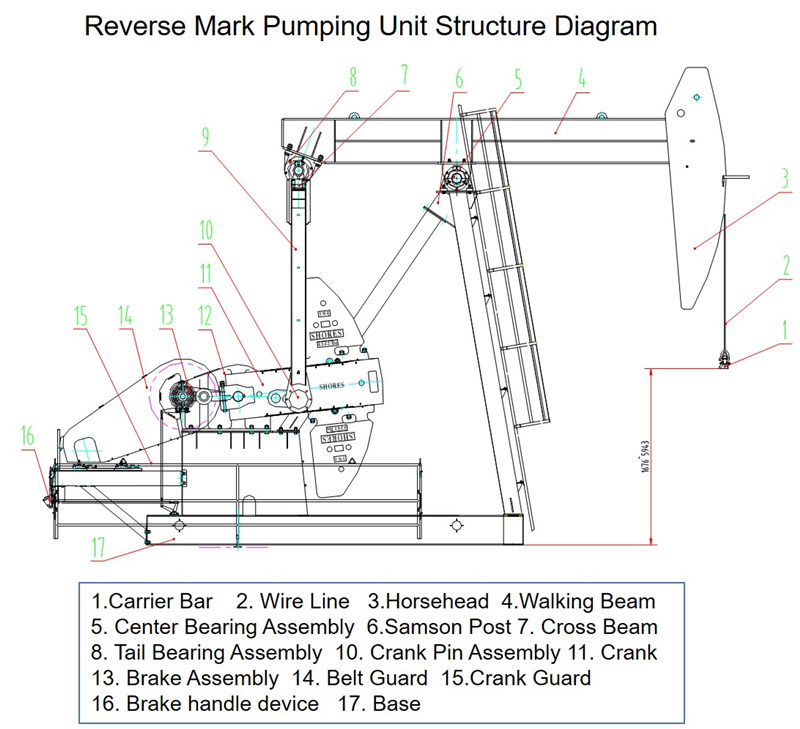

VIEW DETAILS

| Model | ||||||||

| RM912D-427-192 | RM912D-427-168 | RM912D-365-168 | RM640D-365-168 | RM640D-365-144 | RM456D-365-120 | RM456D-305-144 | ||

| Basic Parameters | Rated Polish Rod Capacity (lbs) | 42,700 | 42,700 | 36,500 | 36,500 | 36,500 | 36,500 | 30,500 |

| Stroke Length (in) | 192/168/144/ | 168/144/120 | 168/144/120 | 168/144/120 | 144/120/100 | 120/100/86 | 144/123/101 | |

| Max. Stroke Frequency (r/min) | 8 | 8 | 8 | 10 | 10 | 10 | 10 | |

| Balanced Type | Crank Balanced | |||||||

| Crank Direction | Clockwise | |||||||

| Gear Reducer | Rated Torque(in.lbs) | 912,000 | 912,000 | 912,000 | 640,000 | 640,000 | 456,000 | 456,000 |

| Model | 912D | 912D | 912D | 640D | 640D | 456D | 456D | |

| Gear Type | Double circular arc gear reducer or Involute gear reducer | |||||||

| Reducing Ratio | 28.79 | 28.79 | 28.79 | 28.363 | 28.363 | 28.255 | 28.255 | |

| Center Range (in) | 48.43 | 48.43 | 48.43 | 41.34 | 41.34 | 39.37 | 39.37 | |

| Center Height (in) | 30.91 | 30.91 | 30.91 | 25.98 | 25.98 | 25.59 | 25.59 | |

| Oil Storage quantity (U.S. Gal) | 180 | 180 | 180 | 106 | 106 | 100 | 100 | |

| Lubricant | 20# Gear lubricant in winter,200# Gear lubricant in summer | |||||||

| Sheave Diameter(in) | 50″ | 50″ | 50″ | 50″ | 50″ | 44″ | 44″ | |

| Sheave groove type | 7C | 7C | 7C | 6C | 6C | 5C | 5C | |

| Balance Assembly | Weight of Cranks (Lbs) | 6489×2 | 6489×2 | 6404×2 | 6489×2 | 6404×2 | 5651×2 | 5651×2 |

| Wrist Pin bore Positions (in) | 45 | 45 | 45 | 45 | 45 | 38.98 | 38.98 | |

| 36.54 | 36.54 | 36.54 | 36.54 | 36.54 | 31.38 | 31.38 | ||

| 28.07 | 28.07 | 28.07 | 28.07 | 28.07 | 23.78 | 23.78 | ||

| Wire Line | Type | Φ32(6*37+IWR-1770 MPa) | Φ32(6*37+IWR-1770 MPa) | Φ32(6*37+IWR-1770 MPa) | Φ32(6*37+IWR-1770 MPa) | Φ32(6×37+IWR-1770 MPa) | Φ32(6*37+IWR-1770 MPa) | Φ32(6*37+IWR-1770 MPa) |

| Length (in) | 508 | 460 | 460 | 460 | 410 | 350 | 410 | |

| Structure Unbalance (lbs) | -2700 | -940 | -900 | -900 | 230 | 590 | -500 | |

| Overall Dimensions L*W*H (in) | 566×139×398 | 538×139×369 | 538×139×369 | 530×139×369 | 502×139×357 | 451×139×309 | 479×139×321 | |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP