RockySea Petro Tungsten Plated Tubing & CasingRockySea Petro Petro manufactures Tungsten plated tubing and Casing in China. We have our own factory of Tungsten plated tubing and Casing. RockySea Petro Petro provide the high quality and competitive price on Tungsten plated tubing and Casing for you. Contact us now for Tungsten plated tubing and Casing quotation.RockySea Petro can produce 10,000 tons of various anti-corrosion tubing annually, and plate the ID of 2,000 downhole pump barrels.RockySea Petro is has 7 advanced tungst

VIEW DETAILSRockySea Petro Produced-Water Oilfield Steam GeneratorIncluding high-dryness Oilfield steam generator, supercritical one-through steam generator, oilfield produced water oilfield heat boiler, all-polished rod oilfield steam injection boiler, desulfurization and denitrification steam injection boiler.According to the different requirements of customers, energy-saving, ultra-high pressure and environmental protection boiler types are designed.RockySea Petro has developed new series of mobile on-board and ski

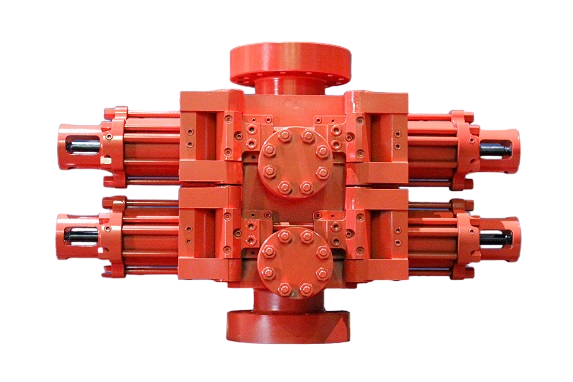

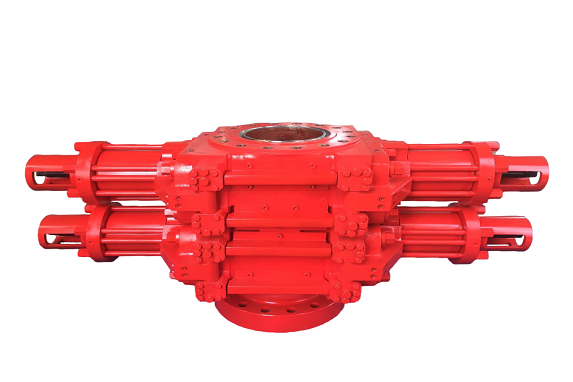

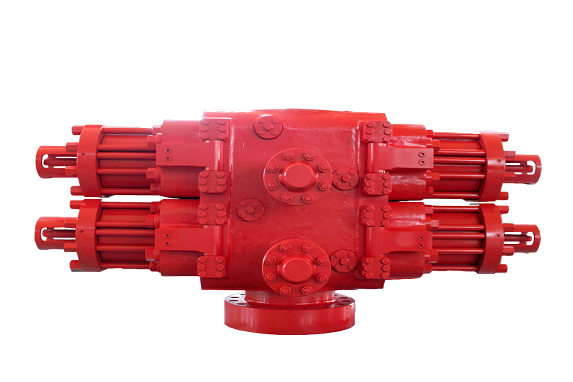

VIEW DETAILSRockySea Petro Quick Lock Ram BOPGreatly reduce the time for replacing the ram and effectively improve work efficiency with safety..No need for large high torque bolts, convenient disassembly and assembly of side doors.Compact structure and reduced weight means more operation roomTraditional blowout preventers all adopted side door bolt connected structures, which require a lot of manpower and time when replacing or repairing the ram every time. On the basis of absorbing the experience and advanced

VIEW DETAILSRockySea Petro Low Profile Pumping UnitLow Profile Nodding DonkeyBeam Balanced Pump JackRM Beam Pump(ReversMark Beam Pump)Conventionalpumping unitRockySea Petro Petro has a strong pumping unit design ability. According to International Standard and China national standard, SanJack Petro has designed and developed a series of pumping units according to market demand.Description Low profile pumping unit is designed for applications where pump height is a critical concern. For locations with overhead irr

VIEW DETAILSRockySea Petro Downhole Pump FittingsWe establishes cooperative relationships with international customers such as Shell, GE, Schlumberger, and JOHN CRANE.Exported to the United States, Europe, Asia and Asia,The standard parts of the sucker rod pump produced by our company are well-selected, precision-made, stable in quality and excellent in performance, .Your Premier Downhole Pump Fittings Manufacturers And Suppliers.Valve Rods Valve rod materials include steel, alloy steel, stainless steel and bra

VIEW DETAILS

| Model | LWS | SL or S |

| Nominal diameter(in) | 7 to 13 5/8 | 9 to 26 3/4 |

| Rated working pressure(psi) | 3000 to 5000 | 3000 to 10000 |

| Processing type | Casting | Casting |

| Material | 4130 or optional | 4130 or optional |

| Metal temperature class | -29~121℃ | -29~121℃ |

| Nonmetal temp. class | -18~121℃ | -18~121℃ |

| Ring gasket | Standard Parts | Standard Parts |

| Dimension and Weight | Based on specific type | Based on specific type |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP