RockySea Petro Single Well Water Cut Analyzer

SANJACK passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement and test equipment, which can meet the requirements of product design, development, production and service and has the only multiphase flow laboratory for Sinopec. The main products are single-screw and twin-screw oil-gas mixed pump, MFM2000 series multiphase flowmeter, LPT multiphase metering device, HPT multiphase metering device, on-line water-bearing analyzer and single-well gas-liquid flowmeter device.

- Full support on your customised requirement

- The strictest quality standards on Flow Meter Device

- 25 years Flow Meter Device manufacturing experience

Description

The ALC05 wellhead Water cut meter is mainly used for water content measurement in oilfield wellheads. It is directly connected with the processing pipeline through two DN50 (other specifications can be customized) flanges to realize online real-time sampling and non-real-time measurement. The structure and measurement method of this wellhead Water cut meter eliminates the influence of gas or other impurities in the crude oil on the water measurement results and improves the measurement accuracy.

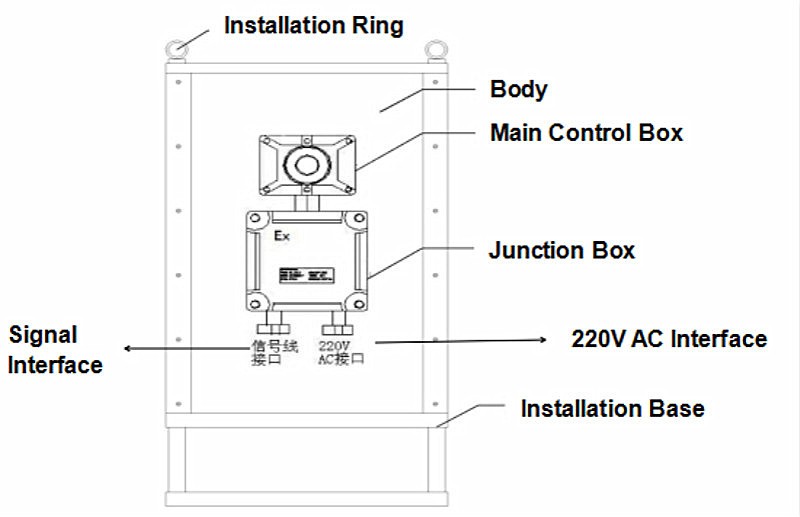

As shown in the figure, the front view includes the main control box and junction box. The main control box is the main measurement control unit of the whole machine, showing the data of the wellhead Water cut meter. Users can adjust the parameters according to the manual. The junction box provides users with amphenol connector for external power supply and communication.

Operating Principle

ALC series wellhead Water cut meter can adapt to extreme conditions such as gas, oil recovery additives and sediment. Even in the case of gas-liquid intermittent flow, the instrument can work normally. The aquifer has won two national patents for technological inventions.

The ALC05 wellhead crude oil water cut meter adopts an innovative dual-section structure, which automatically switches the measuring section and bypass section. The measurement process consists of the following steps: switching sampling, preliminary measurement and analysis, heating stratification, scanning measurement of water content layer, and calculation of comprehensive water content. When the liquid flow channel is switched to the bypass section, the original medium flowing through the measurement section is intercepted and can be stationary, heated, stratified and scanned at any time interval. Because of the relatively static measurement environment, gas, liquid and impurities have enough stratification time and heating assistance, good measurement accuracy can be achieved. In addition to the output water content measurement results, the instrument can even measure the gas-liquid ratio under operating conditions (dissolved gas can not be measured).

Features

Wellhead/Single Well Water cut meter is a kind of MFM2000 series multiphase flowmeter with the following characteristics:

- Intelligent communication, the software can be upgraded on-site.

- In addition to display and output, the measurement results also have the function of historical data storage, which stores the historical data of the online measurement results.

- The static time and heating temperature can be set according to the parameters, which ensures a good separation effect of gas-liquid and impurities, and provides a guarantee for high-precision measurement.

- The relative static measurement process is realized by using the principle of online sampling and online measurement.

Advantages

Advantages of Single Well Water Cut Analyzer:

- With an automatic heating device, the upper limit of heating temperature can be set to meet the temperature requirements of medium stratification under different working conditions.

- Installation is convenient and fast, without the requirement of a front and rear straight pipe sections, and is insensitive to flow velocity.

- Chinese characters + digital display in situ, original 3-key non-contact keys, greatly facilitating the user’s operation of explosion-proof meter head.

- According to the requirement of wellhead water cut measurement, the time and times of daily measurement can be set to get the water cut of each measurement and calculate the comprehensive water cut of a day.

- It has the function of temperature control. It can set the target temperature and has a built-in temperature sensor. The instrument can measure and display temperature without an external temperature transmitter and compensate for the temperature of water content measurement results.

Data Sheet

Data Sheet of Single Well Water Cut Analyzer

- Power supply: AC220V, 50Hz

- Current: ≤ 3A

- Ground type: whole machine working ground; lightning protection ground; Internal circuit shielding ground; shell protection ground

- Electrical connection: M20*1.5 internal thread

- Display: LCD display

- Designed temperature: 0~160℃

- Designed pressure: 2.5MPa

- Protection class: IP65

- Explosion-proof class: ExdⅡBT4

- Installation place: Pipeline on wellhead or in metering room; horizontal or vertical installation

- Body material: SS304

- Flange material: SS304

- Installation method: Section Installation, Flange Installation DN50PN2.5

- Environment temperature: -40 ~ 65℃

- Accuracy: ±3%

- Measuring range: 0% ~ 100%

- Material contacted the liquid: SS304 + polytetrafluoroethylene

- Signal output: 4~20mA current, RS485/MODBUS communication

Application Cases