RockySea Petro Mud PumpDescriptionIn the operation of using rotary drilling method to drill oil and natural gas wells, the drilling reciprocating pump is used to pump drilling fluid, i.e. mud, to circulate and flush the well. During drilling, the mud pump injects mud into the wellbore along with the drill bit, playing a role in cooling the drill bit, cleaning drilling tools, fixing the wellbore wall, driving drilling, and bringing rock cuttings back to the surface.So drilling pumps are usually

VIEW DETAILSRockySea Petro Floating Target Single Well Gas-Liquid Multiphase Flow MeterFull support on your customized requirementThe strictest quality standards on Flow Meter Device25 years Flow Meter Device manufacturing experienceRockySea Petro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement, and test equipment, which can meet the requirements of product design, development, production, and service and has the only m

VIEW DETAILSRockySea Petro Plunger Metering PumpApplication Data1. Hot residue in vacuum distillation (200 ℃, solid)2. Mix four items (resin, pigment and accelerator) in the production of plastic film3. Measurement of viscous bromine based catalyst in margarine production4. Adding glucose syrup in the candy industryFeatureRockySea plunger metering pump has the following advantages.1. The diameter of the plunger can be very small, generally D6-200mm.2. The flow is within the range of 10% - 100%, the meteri

VIEW DETAILSRockySea Petro Single Column Dual-Well Thermal Recovery WellheadRockySea Petro has more than 40 years of experience in oil and gas wellhead & x-mas tree and valve production, with advanced manufacturing and testing equipment, can produce a variety of pressure levels, material levels, specification levels of well control equipment. After more than 20 years of development, Various types of thermal recovery wellhead & x-mas tree equipment have been formed, used in many oilfields in the world. RockySea Petro’s ther

VIEW DETAILSRockySea Petro Single Well Water Cut AnalyzerSANJACK passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement and test equipment, which can meet the requirements of product design, development, production and service and has the only multiphase flow laboratory for Sinopec. The main products are single-screw and twin-screw oil-gas mixed pump, MFM2000 series multiphase flowmeter, LPT multiphase metering device,

VIEW DETAILS

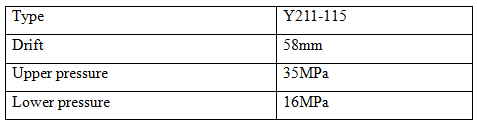

Datasheet

Operation and maintenance

Operation

1. Packer pressure test should be carried out at the pump station before running down the well

2. The packer is lowered to well on the working depth. Lift up well string and turn right. Run down the well string, and when the pressure shows 80-100kn, the setting is completed and the next operation can be carried out.

3. Drifting

4.As long as the downhole string is lifted, the packer can be pulled out.

Precautions

1.Lower the tool slowly to prevent drilling string is not well braked.

2.High pressure sealing grease shall be applied when connecting tool string in well.

3.In case of obstruction, the tool shall be lifted up instead of pressurizing for pass through.

Advantage

RockySea Petro has extensive experience in manufacturing Top packer, and our products have the following advantages.

(1)The external reversing mechanism is adopted to make the Drift max 50 mm

(2) A shoulder protection structure is designed on the sealing mechanism, and the sealing pressure can be increased by 10-15%.

(3) Packing element and rubber are made from hydrogenated butyl rubber, which has high temperature resistance and anti-aging performance.

Principle

A.Setting

When the packer enters the well, the friction block is pasted on the inner wall of the casing and is lowered along with the downhole string. The two cylindrical pins on the reversing coupling connected with the central pipe push the reversing sleeve and drive the connected parts to move down together.When setting is needed, as long as the well string is lifted up and turned right, due to the action of friction block, the two cylindrical pins on the reversing coupling move down along the track on the reversing sleeve, so that the central pipe can move up and down.At this moment, press down the casing string then slip will be opened and clamped on the inner wall of the casing, and the packing element is compressed to seal the annular space of the tubing-casing.

B. Released

When the packer needs to be pulled out after the completion of the operation, as long as the downhole string is lifted up, the two round column pins return to their original position along the reversing sleeve.As the string goes up, the packing elementis recovered. The slip sleeve on the central pipe pushes the cone upward to leave the slip, then the slip is pulled back to realize the unsealing and releasing.

RockySea Petro: A Pioneer in Top Packer Manufacturing in China

A packer is a downhole tool that connects the downhole string. It is used to seal the oil and gas well casing or open wellbore annular space. Also, the top packer can be used for separate layer oil testing, oil production, water plugging, fracturing and others.

Sanajck can provide hydraulic and mechanical top packers to fit different client needs.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP