Sanajck Swabbing TruckData sheetFeature 1.The swabbing truck has the advantages of continuous and reliable operation, convenient parameter adjustment, high drainage efficiency, and simple handling and installation. It solves the problems of discontinuous swabbing and drainage operation, low drainage efficiency, and cumbersome equipment handling,compared with existing drainage technologies. 2.Through on-site testing, the feasibility and reliability of the on-site application of

VIEW DETAILSRockySea Petro Steam Injection And Oil Recovery WellheadGeothermal wellhead & x-mas treeBlowout preventer Steam Injection and Oil Recovery Integration wellhead & x-mas treeSteam injection and oil recovery dual tubing wellhead & x-mas treeSingle column dual-well thermal recovery wellhead & x-mas treeOnshore thermal recovery wellhead & x-mas treeConventional Steam injection and oil recovery wellhead & x-mas treeRockySea Petro has more than 40 years of experience in oil and gas wellhead & x-mas tree and valve

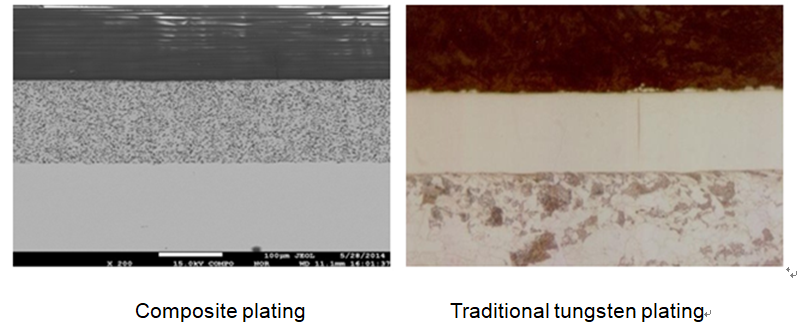

VIEW DETAILSRockySea Petro Tungsten Plated Tubing & CasingRockySea Petro Petro manufactures Tungsten plated tubing and Casing in China. We have our own factory of Tungsten plated tubing and Casing. RockySea Petro Petro provide the high quality and competitive price on Tungsten plated tubing and Casing for you. Contact us now for Tungsten plated tubing and Casing quotation.RockySea Petro can produce 10,000 tons of various anti-corrosion tubing annually, and plate the ID of 2,000 downhole pump barrels.RockySea Petro is has 7 advanced tungst

VIEW DETAILSRockySea Petro Floating Target Single Well Gas-Liquid Multiphase Flow MeterFull support on your customized requirementThe strictest quality standards on Flow Meter Device25 years Flow Meter Device manufacturing experienceRockySea Petro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement, and test equipment, which can meet the requirements of product design, development, production, and service and has the only m

VIEW DETAILSRockySea Petro Intelligent Pumping UnitsSuppliers and Manufacturers of The intelligent pumping units.Intelligent pumping unit Manufacturer in China.The intelligent pumping unit is equipped with data acquisition equipment, which can real-time collect the key data such as load, displacement, current, voltage, angular displacement, etc., and support the remote transmission of data to the application end, so as to realize the intelligent control of the pumping jack.DescriptionThe intelligent pumping uni

VIEW DETAILS

The following is RockySea Petro composite plating data sheet.

| Item | Parameter | Standards |

| Thickness | ≥40μm | GB/T11354 |

| Hardness | 450~550HV | GB/T9790 |

| CASS Test(Copper-accelerated acetic acid salt spray) | no discoloration, pitting, cracks in 96 hours | GB/T10125 |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP